- GST NO. : 27AQUPS9969A1ZW

indratechnologies@gmail.com

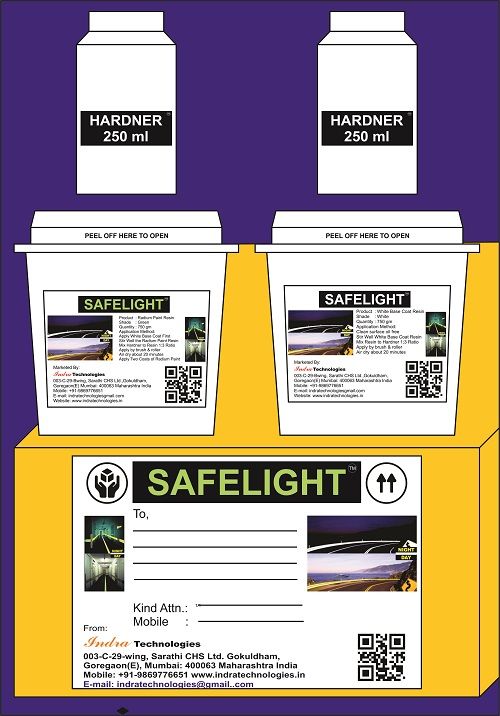

| Business Type | Manufacturer, Exporter |

| Brand Name | Safelight |

| Material | Radium-based |

| Color | Green In The Dark |

| Click to view more | |

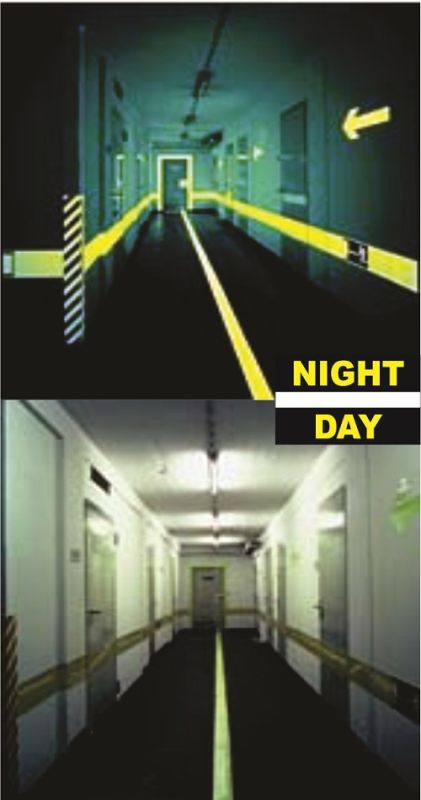

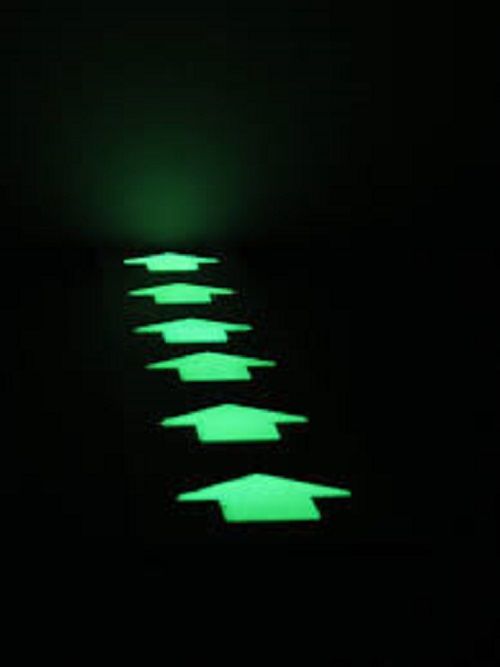

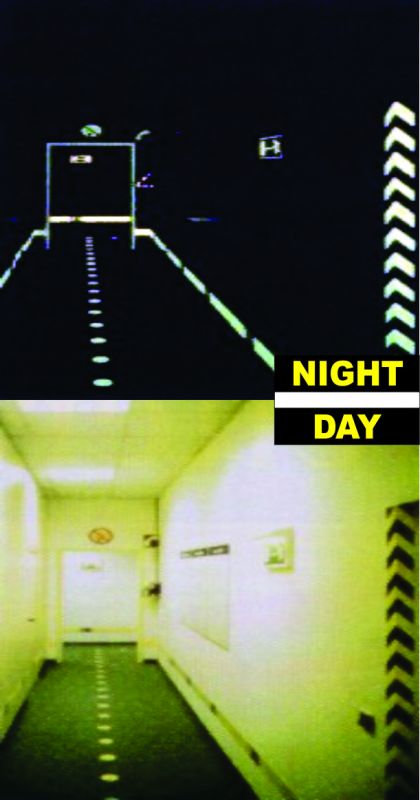

Product Details

ChatGPT said: Safelight Radium Paint for Crude Oil Refineries – Advanced Photoluminescent Safety Coating for High-Risk Industrial Environments Crude oil refineries operate in some of the most hazardous and high-risk industrial conditions, where the presence of flammable materials, high-pressure systems, complex pipelines, and explosive atmospheres makes safety and emergency preparedness absolutely critical. In such environments, even a brief power failure or visibility loss during an emergency can lead to catastrophic consequences. Safelight Radium Paint, also known as Glow in Dark Paint, Night Glow Paint, Photoluminescent Paint, Luminous Paint, or Phosphorescent Paint, is a cutting-edge safety coating designed to provide continuous, maintenance-free visibility and guide personnel safely even in complete darkness. By absorbing natural or artificial light during regular operations, this advanced coating glows brightly for 10–12 hours without any electricity, helping workers navigate, evacuate, and locate safety equipment during critical situations. 🛢️ Key Safety Benefits in Refinery Environments Reliable Visibility During Emergencies: Refineries are highly vulnerable to fire, explosion, gas leaks, chemical spills, and power outages. Safelight Radium Paint ensures that escape routes, emergency exits, safety signage, and critical pathways remain clearly visible even when conventional lighting systems fail. Life-Saving Evacuation Tool: During high-risk incidents where seconds can mean the difference between life and death, Photoluminescent Paint acts as a silent safety guide, leading personnel safely toward exits, muster points, and emergency shelters. Cost-Effective Alternative to Conventional Safety Systems: Backup power systems, emergency lamps, and standby generators require heavy capital investment, regular maintenance, and continuous energy consumption. Safelight Radium Paint is a one-time, low-cost application that requires no maintenance, no power, and no operational expense for over 5 years — making it a highly economic substitute for traditional emergency lighting. Reduction in Insurance Premiums: Insurers often consider facilities equipped with Luminous Paint and Phosphorescent Paint as lower-risk operations. Installing such passive safety measures can lead to significant reductions in annual insurance premiums, translating into long-term financial savings. Regulatory Compliance and Safety Audit Readiness: Photoluminescent safety markings help refineries comply with OISD (Oil Industry Safety Directorate) norms, fire safety codes, and emergency evacuation guidelines, ensuring successful safety audits and certification processes. 🏭 Applications in Crude Oil Refineries Emergency exits, staircases, corridors, and evacuation pathways Control rooms, sub-stations, and pump houses Firefighting and safety equipment zones (extinguishers, alarms, hydrants, PPE stations) Hazardous chemical storage areas and gas manifold zones Pipelines, catwalks, platforms, and loading/unloading bays Assembly points, muster zones, and first-aid stations 📊 Case Study: Successful Evacuation During an Explosion Incident A major crude oil refinery in Gujarat installed Safelight Photoluminescent Paint on all evacuation routes, emergency doors, safety equipment locations, and high-risk operational zones as part of a safety modernization initiative. A few months later, a valve malfunction caused a fire and subsequent power failure in a processing unit during the night shift. Despite the sudden blackout and rising panic, the Glow in Dark Paint provided bright, visible guidance throughout the affected area. Workers were able to follow illuminated escape routes and reach assembly points within minutes, resulting in zero injuries and no loss of life. The refinery’s post-incident safety audit noted a 42% reduction in evacuation time compared to previous drills. The insurance company also rewarded the facility with a 16% re