- GST NO. : 27AQUPS9969A1ZW

indratechnologies@gmail.com

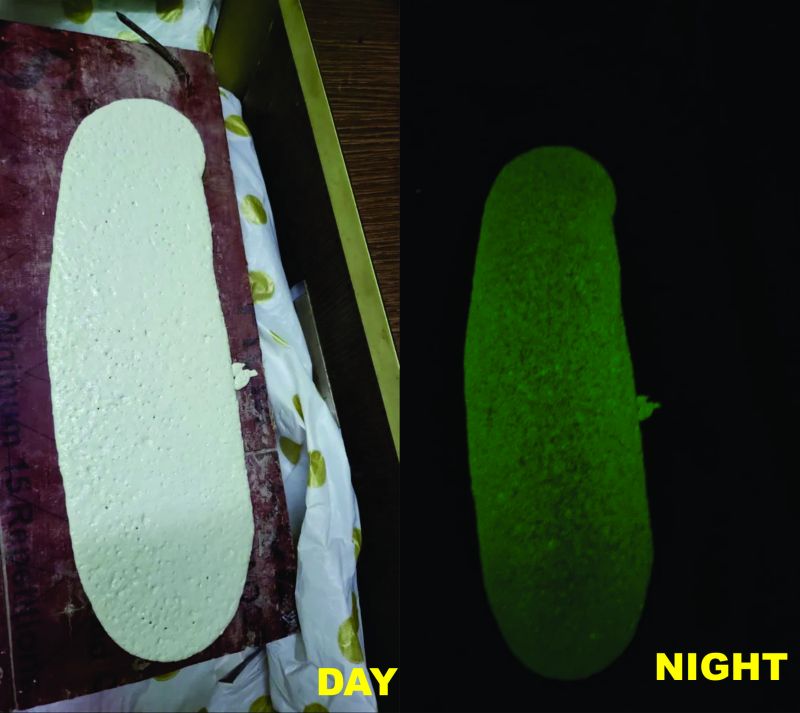

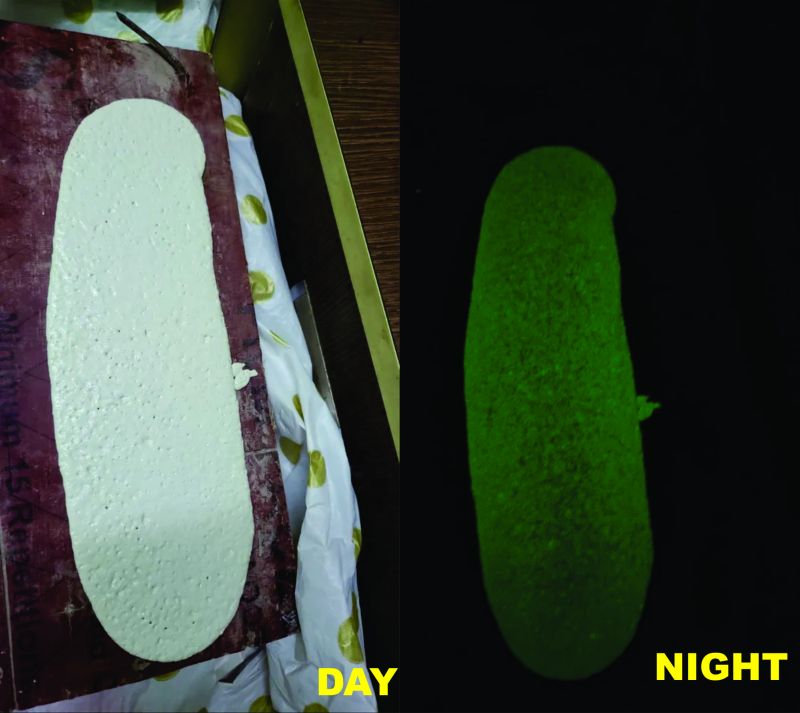

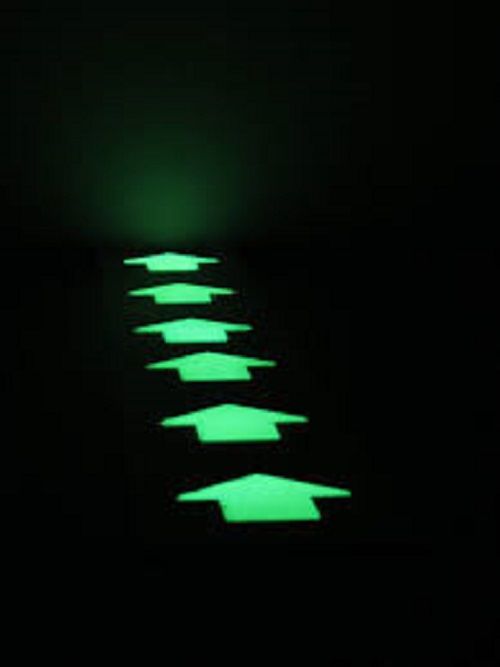

Night Glow Paints

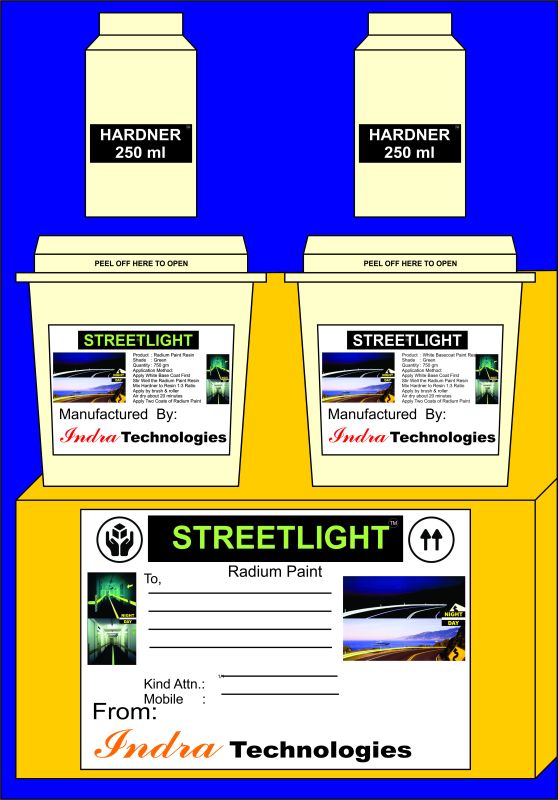

Leading Manufacturers, Exporters, Wholesaler and Retailer of Crash Barrier Safelight Radium Paint, Ig 3 Safe Light Radium Paint, Ig 6 Night Glow Lane Marking Paint, Ig 6 Night Glow Paint, IG6 Night Glow Photoluminescent Phosphorescent Paint, IGT 17 Coal Mines Safety Radium Paint, IGT 42 Trailer Radium Paint, IGT 49 Safelight Night Glow Paint, IGT 59 Cosmetic Luminescent Paint, Radium Helipad Marking Paint, Radium Paint for Crash Barrier, Radium Paint Petro Chemical, Radium Paints for Tunnels, Safelight Radium Paint for Aerospace & Airplane Industry, Safelight Radium Paint for Army & Defense Industry, Safelight Radium Paint for Commercial Complex, Safelight Radium Paint for Commercial Motor Vehicles,, Safelight Radium Paint for Crude Oil Refineries, Safelight Radium Paint for Curved Stones, Quarter Stones, Safelight Radium Paint for Electric Power Plant, Safelight Radium Paint for Electronics Plant and Safelight Radium Paint for Malls from Mumbai.

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Radium Paint |

| Application | Crash Barriers, Road Dividers, Flower Beds etc. |

| Material | Photoluminescent Coating |

| Color | Greenish |

| Visibility | Up To 1 Km In Darkness |

| Glow Source | Absorbs Sunlight Or Ambient Light |

| Service Life | Up To 5 Years |

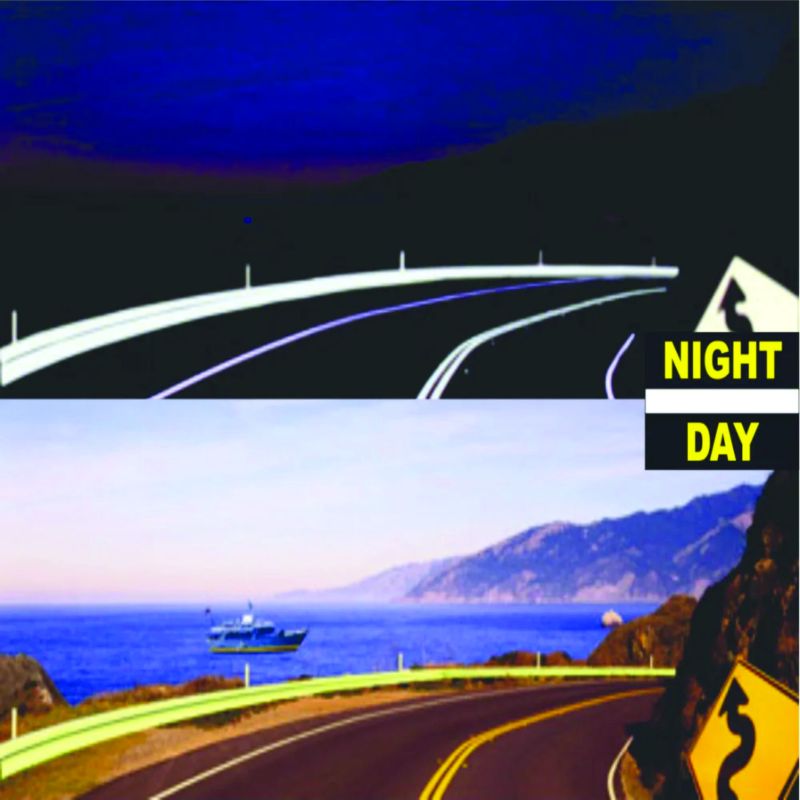

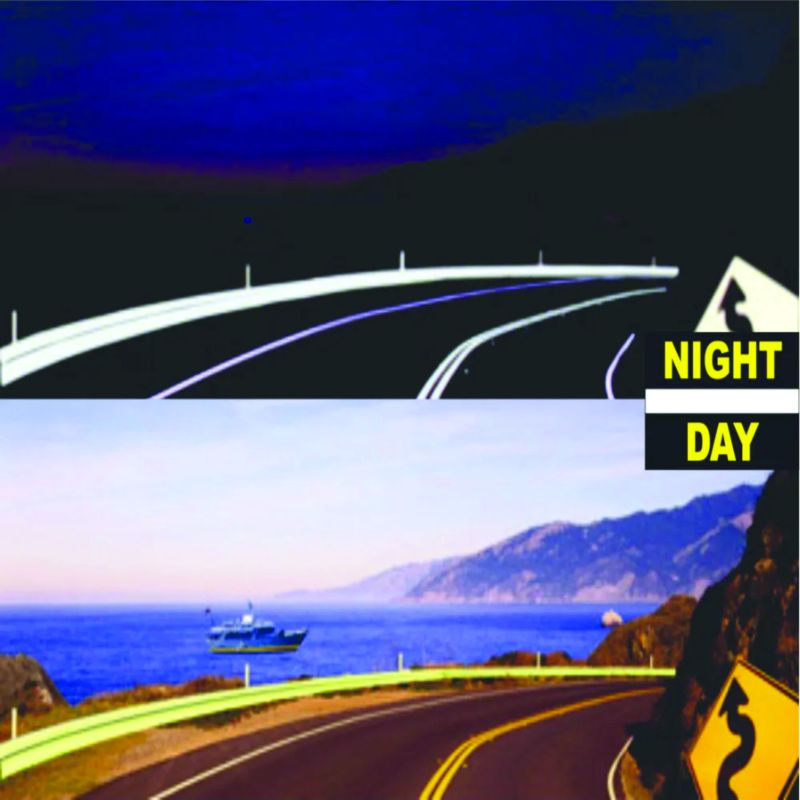

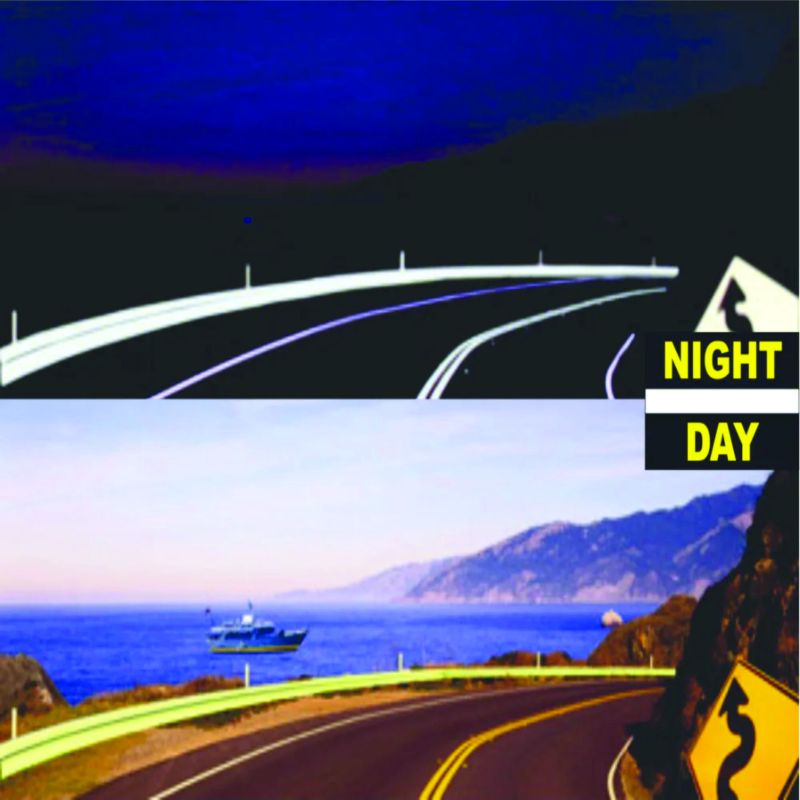

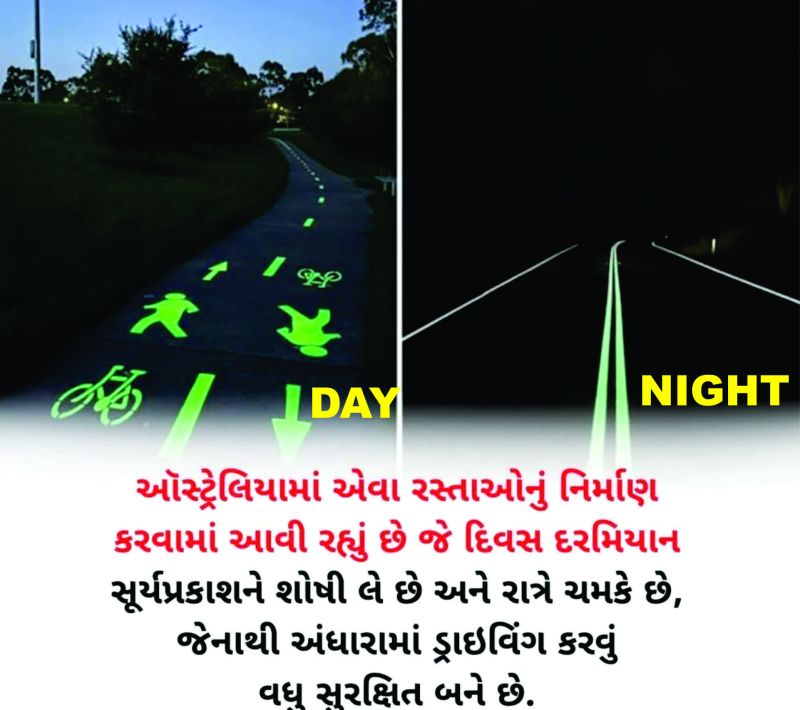

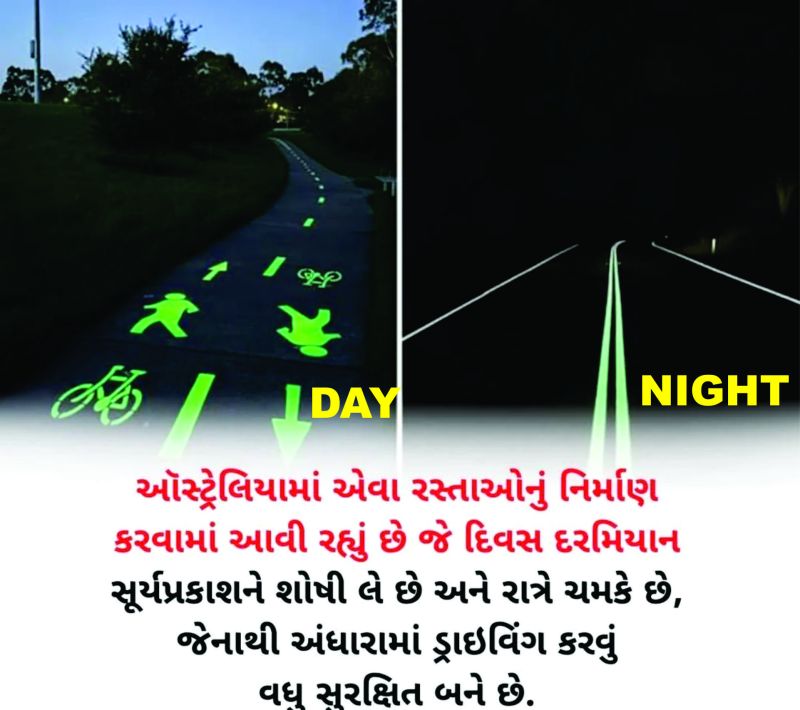

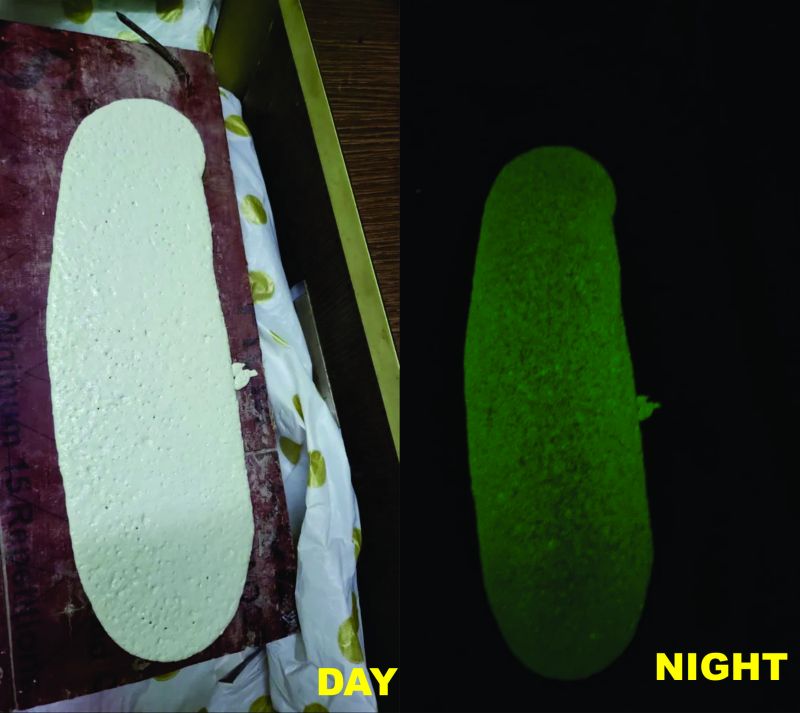

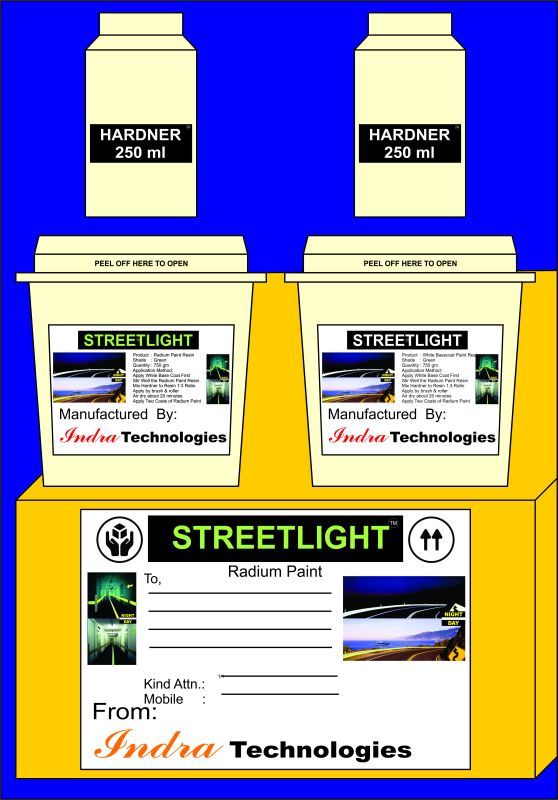

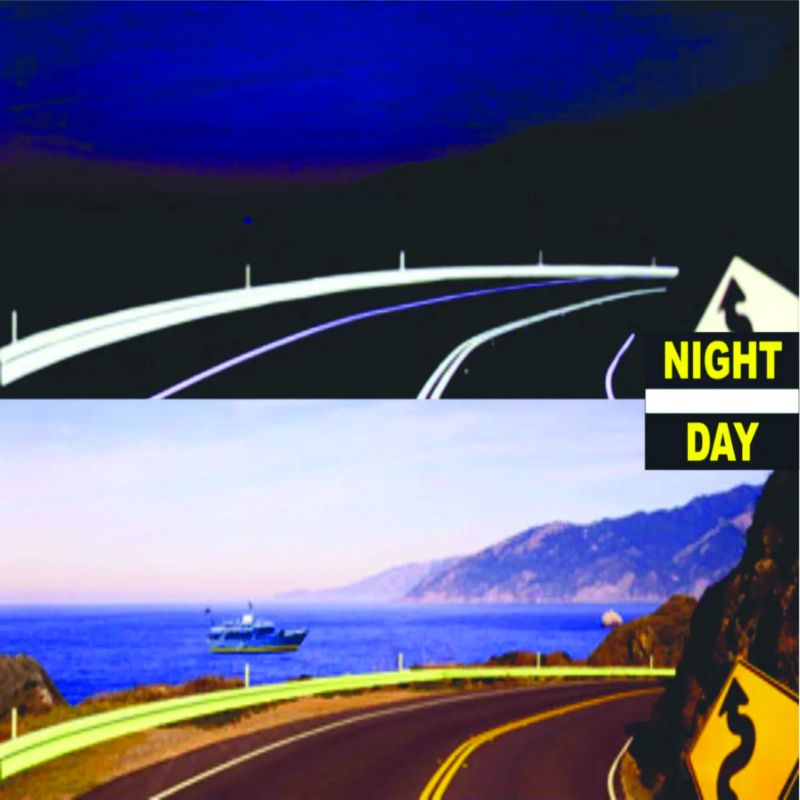

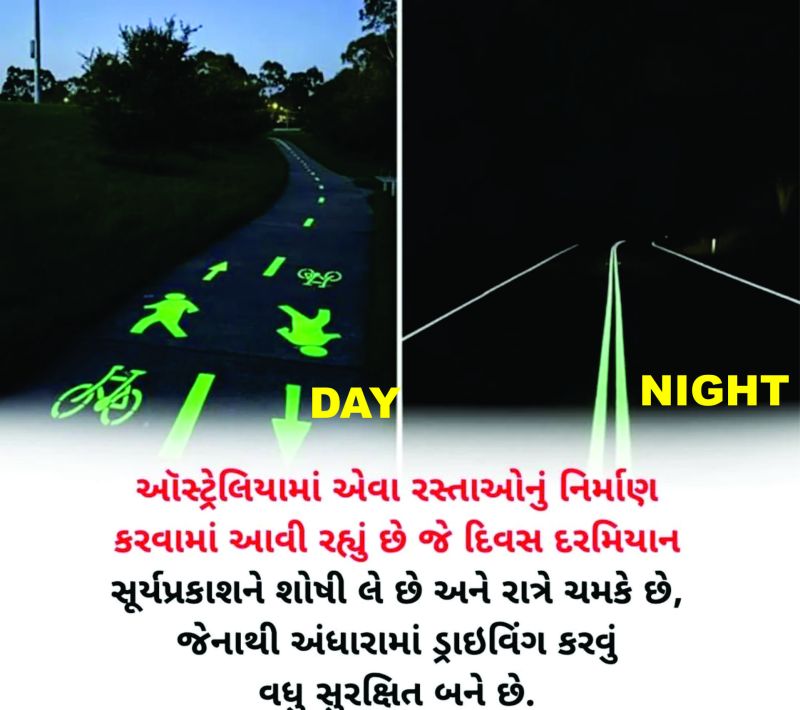

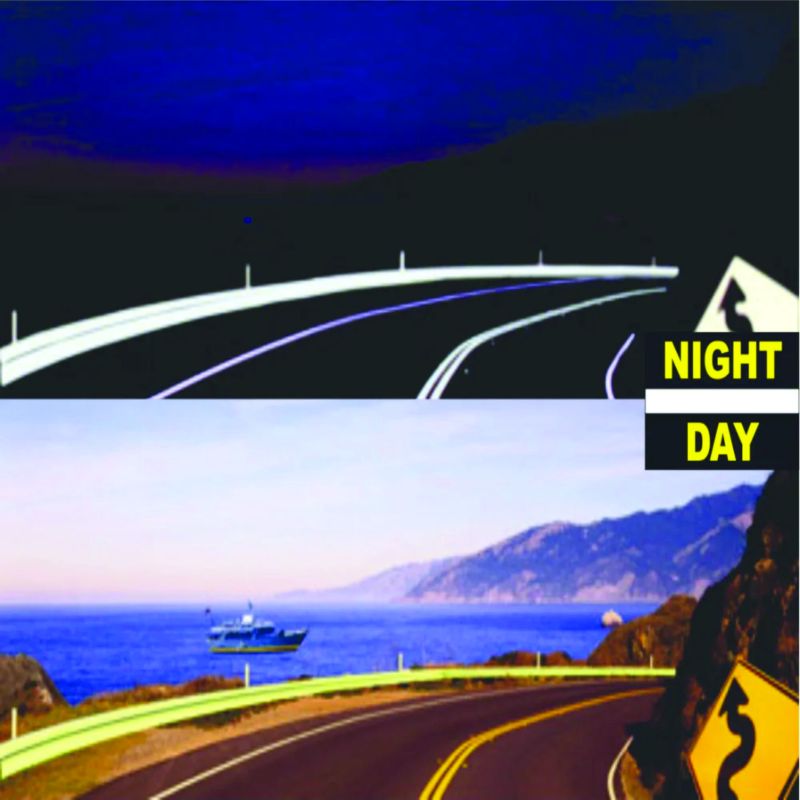

Streetlight Radium Paint is a next-generation photoluminescent coating designed for highways, expressways, and accident-prone areas. Unlike traditional reflective paints that rely on headlights, this paint absorbs sunlight or ambient light and glows naturally in the dark, visible from up to 1 km away. It provides drivers with early warnings, reducing accidents and improving road safety.

Key Applications-

Crash barriers (primary safety structures)

-

Road dividers, flower beds, and curb stones

-

Quarter stones and kilometer stones

-

Sharp curves, underpasses, hills, and poorly lit stretches

-

City roads, rural roads, parking lots, housing societies, institutional campuses

✓ Visibility up to 1 km in darkness

✓ Continuous glow for safe night driving

✓ Works without headlights – unlike reflective paints

✓ Prevents lane-crossing and run-off-road accidents

✓ Cost-effective: ₹5 lakh/km vs. ₹100 lakh/km for streetlights

✓ Zero electricity, zero maintenance, eco-friendly

✓ Durable, weather-resistant, 5-year life

✓ Reduces carbon footprint compared to electric lighting

-

Streetlights: ₹100 lakh/km + maintenance + electricity

-

Radium Paint: ₹5 lakh/km, no operating cost, long-lasting performance

-

Glow Duration: Visible up to 1 km in darkness

-

Glow Source: Absorbs sunlight or ambient light

-

Substrates: Concrete, metal, stone

-

Properties: Weather-resistant, dust-proof, fog-proof, heat & rain stable

-

Service Life: Up to 5 years

On highways and rural roads without streetlights, crash barriers and dividers coated with Streetlight Radium Paint stay visible even in pitch darkness. Drivers approaching at high speed notice the glowing outline early, gaining enough time to brake safely. This reduces both minor collisions and fatal accidents.

Ideal For

-

Highways & expressways

-

Rural and village roads

-

Industrial areas & parking lots

-

Housing societies & institutional campuses

-

Accident-prone zones with poor/no street lighting

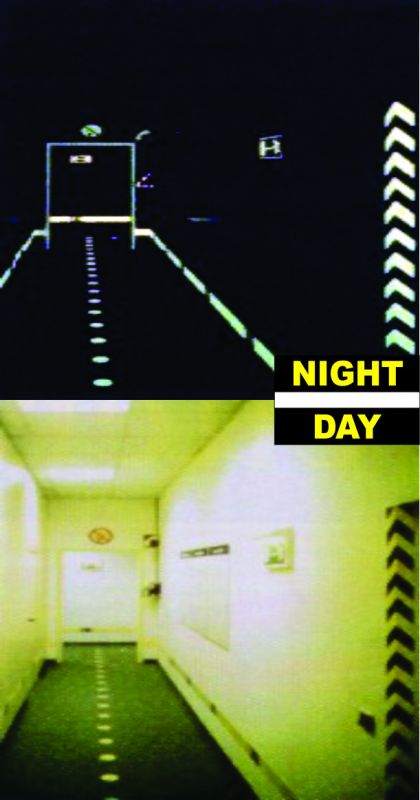

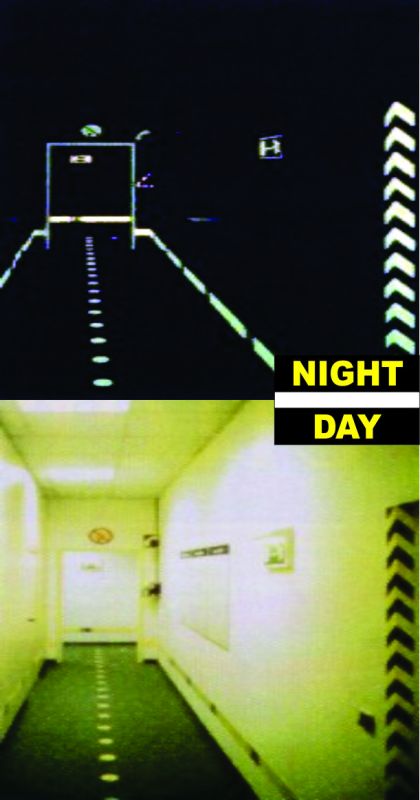

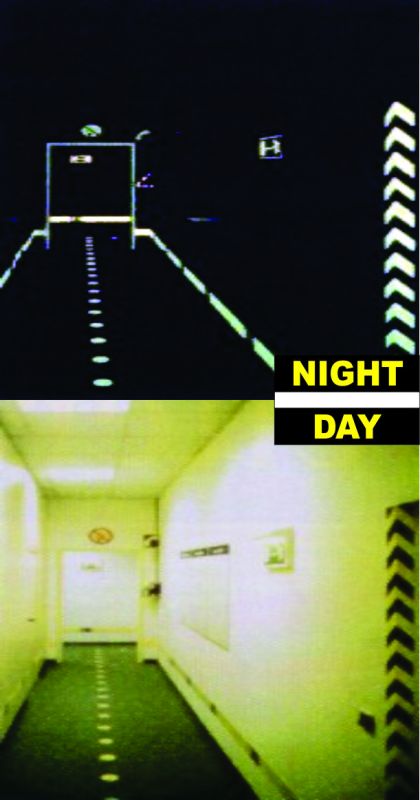

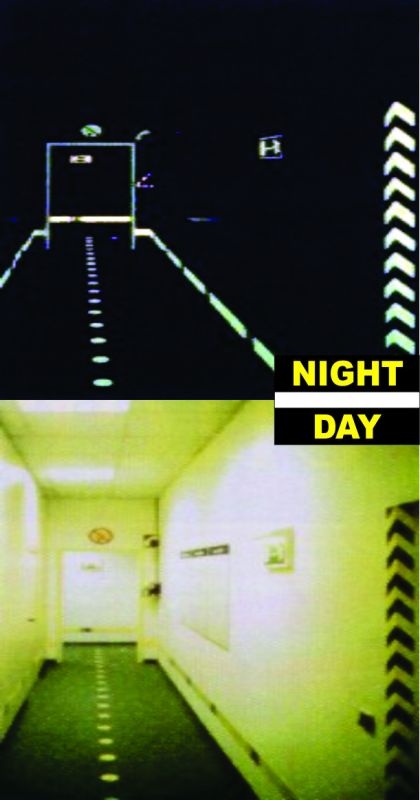

| Business Type | Manufacturer, Exporter, Supplier |

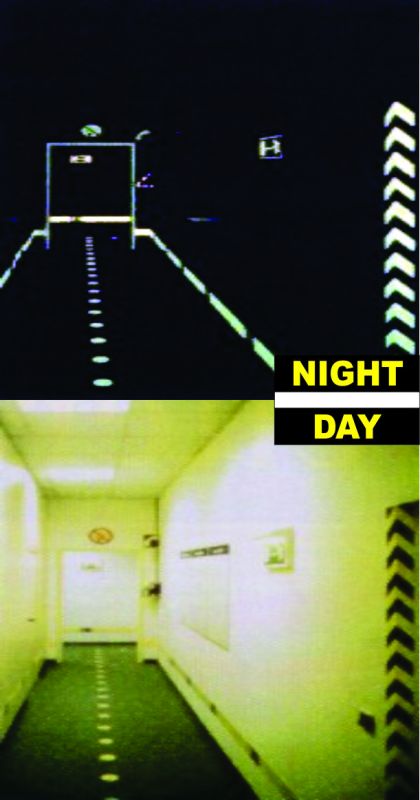

| Type | IG 3 Safe Light Radium Paint |

| Application | Lane Marking In Power Plants |

| Color | White In Daylight, Green/blue In Darkness |

| Charging Time | 3-4 Hrs Under Tube Light |

| Glow Duration | 5-6 Hrs In Complete Darkness |

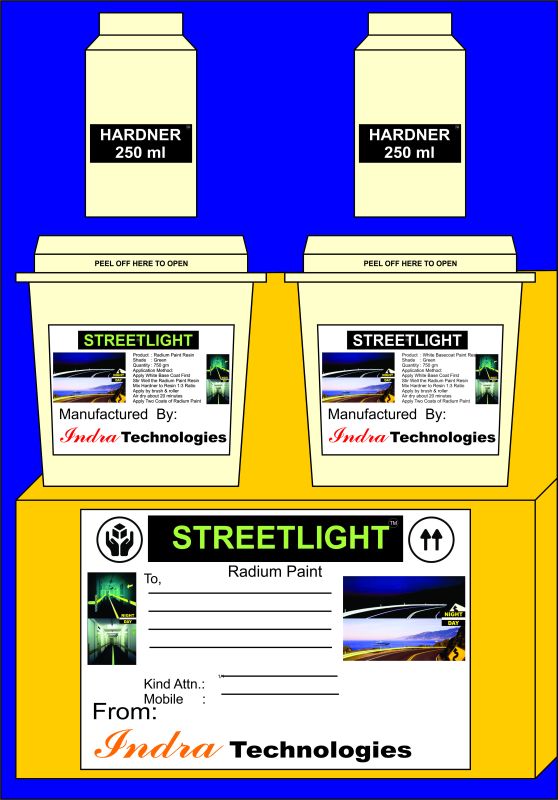

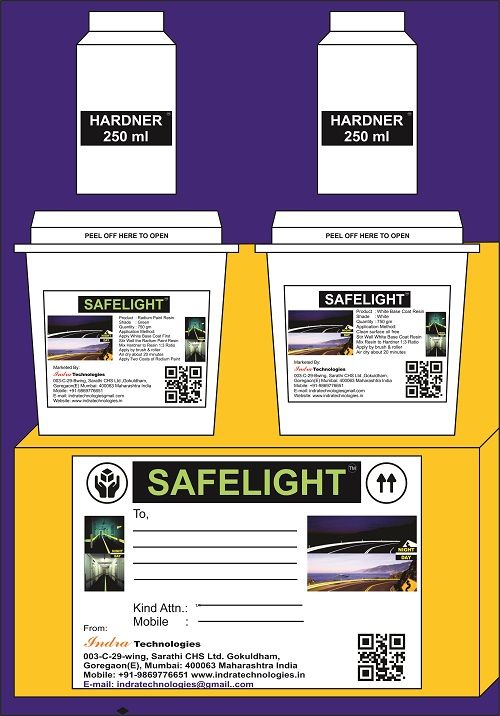

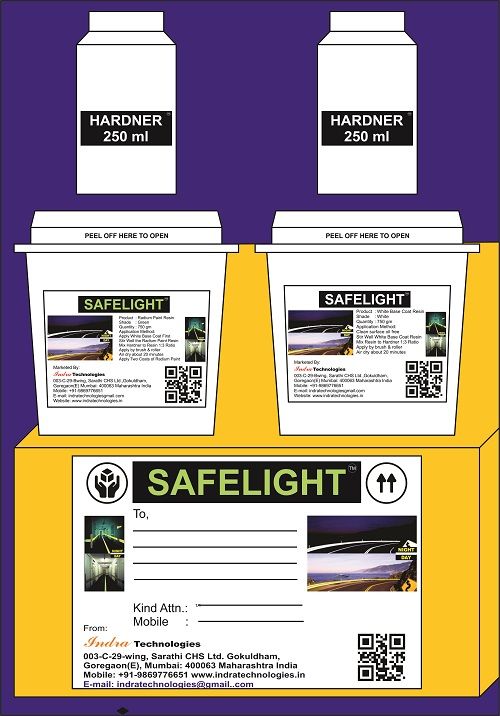

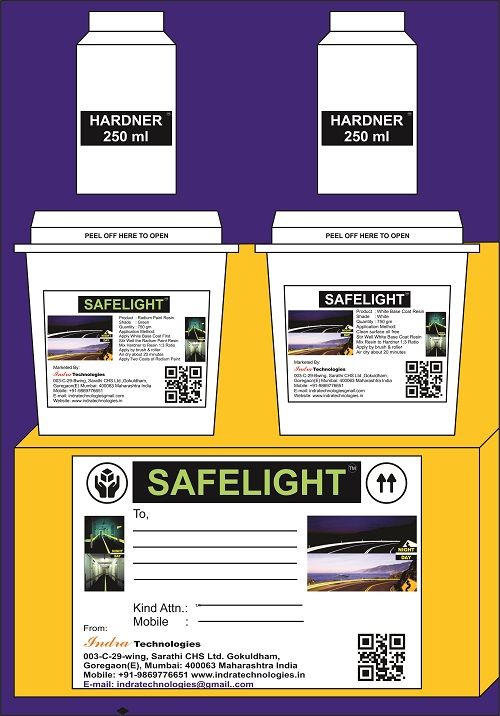

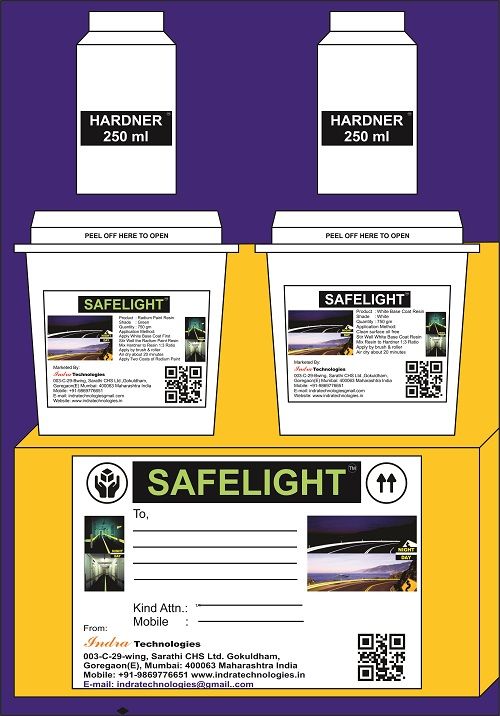

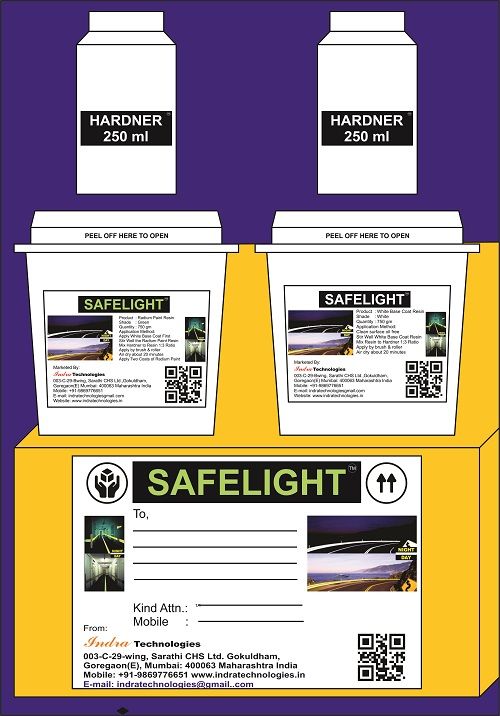

| Packing | 1 Liter, Two-pack System |

| Coverage | 70 Sq. Ft. Per Liter |

| Material | Polyurethane Resin-based |

| Finish | Smooth, Glossy |

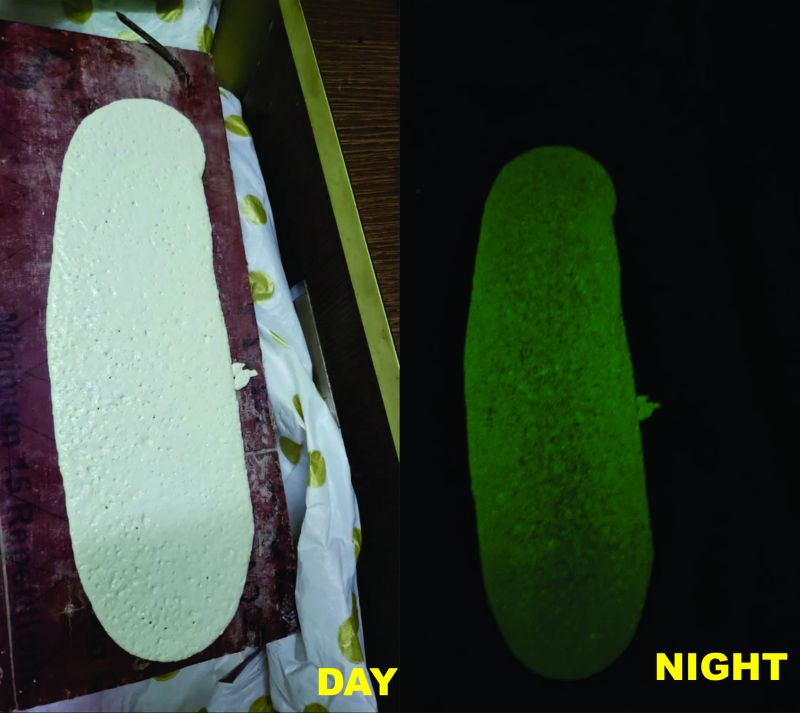

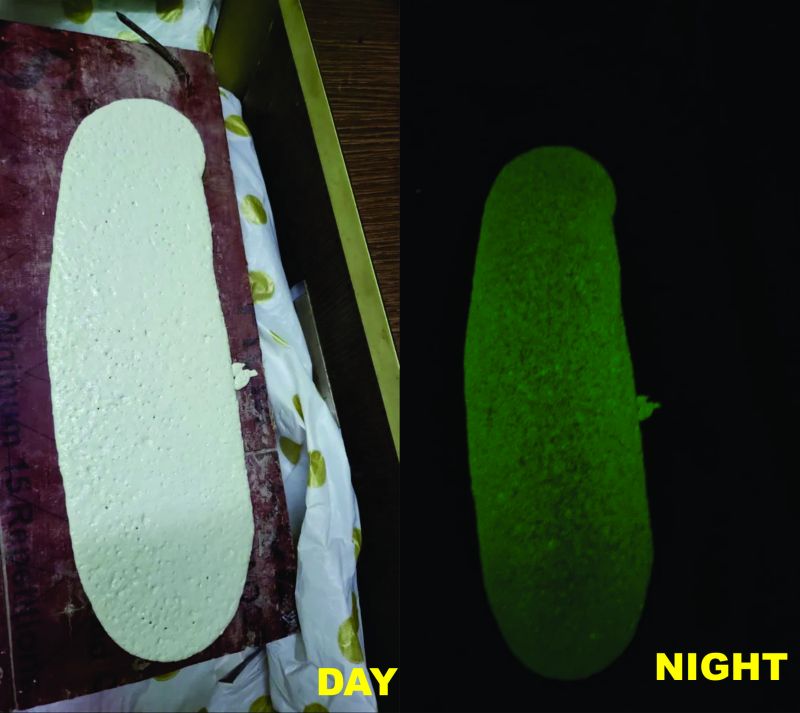

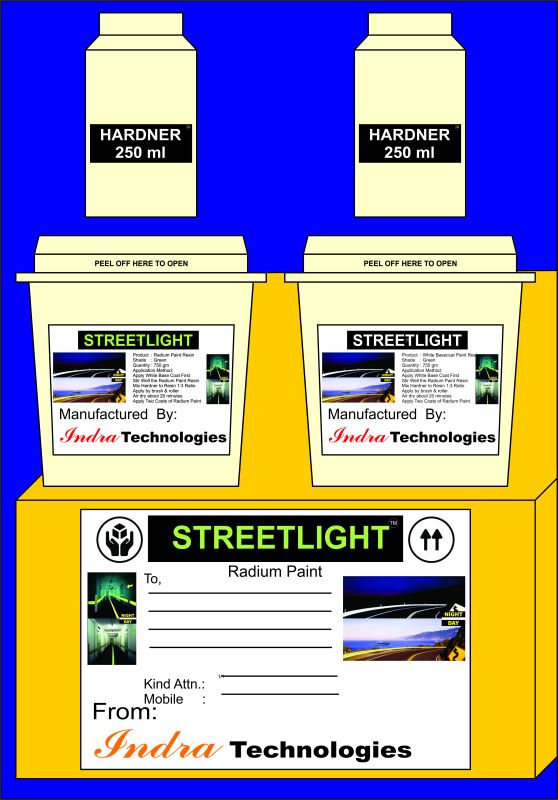

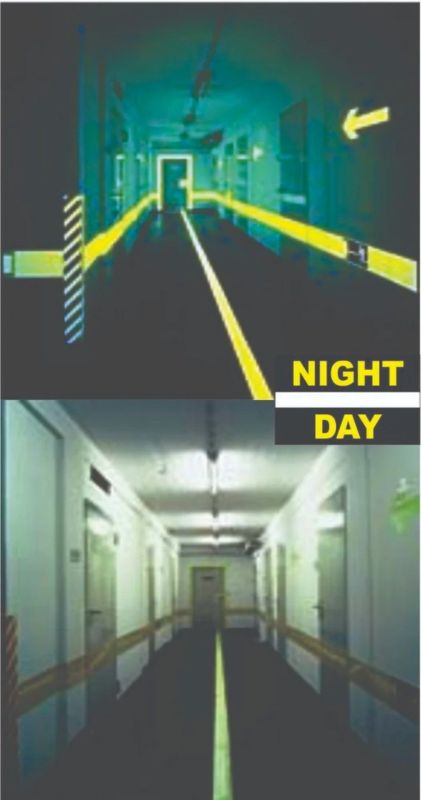

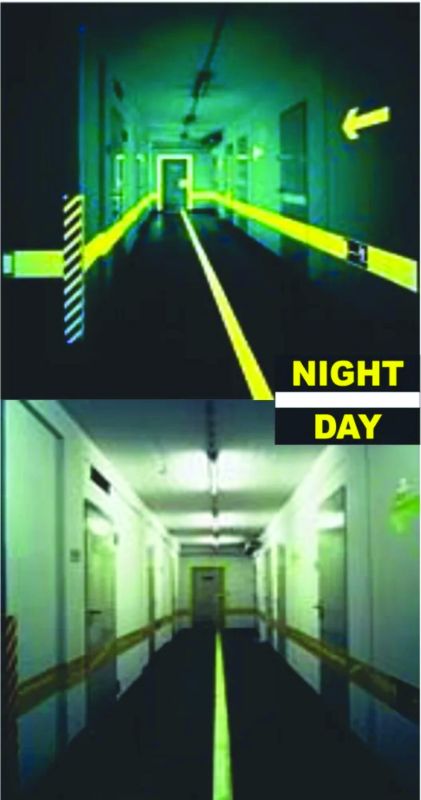

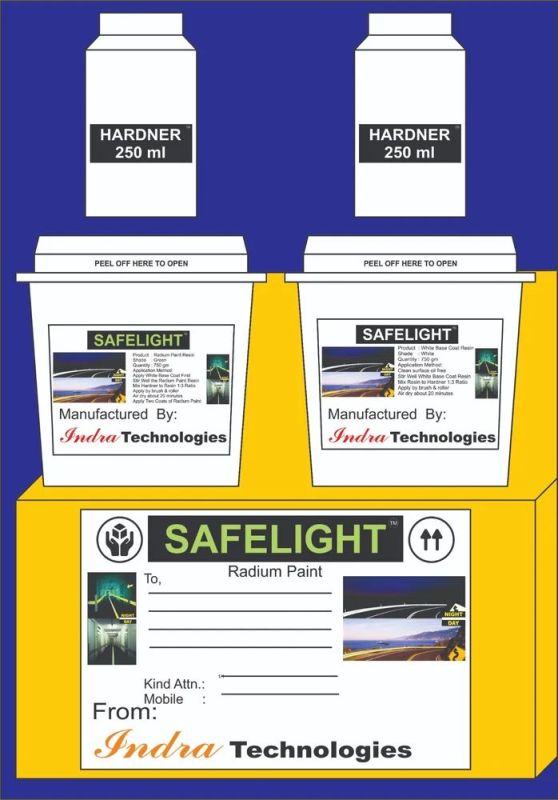

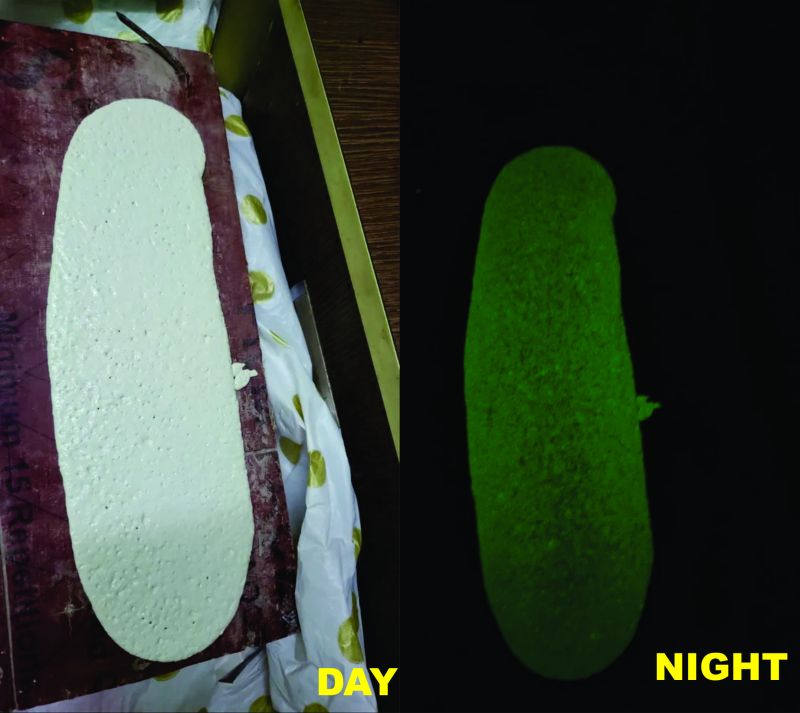

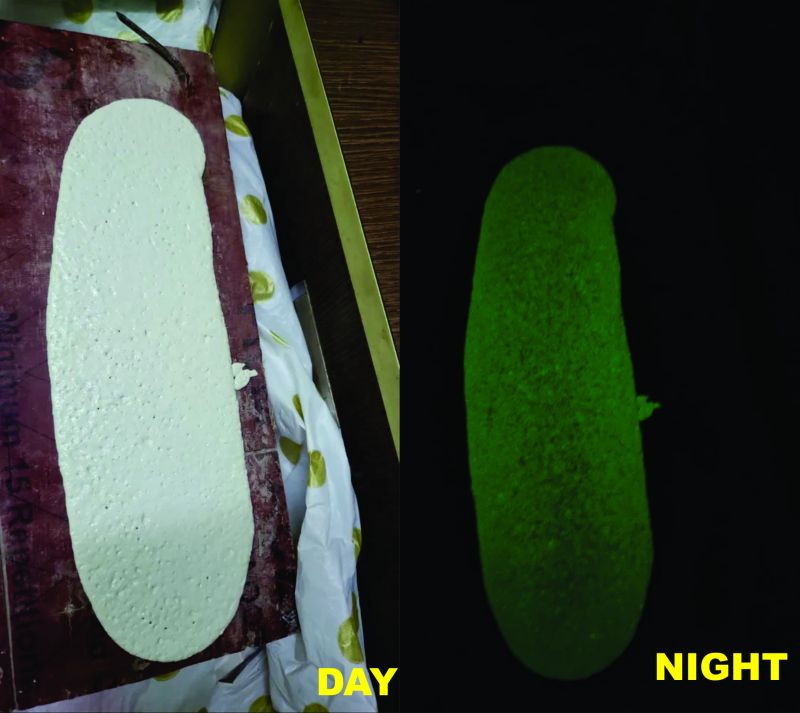

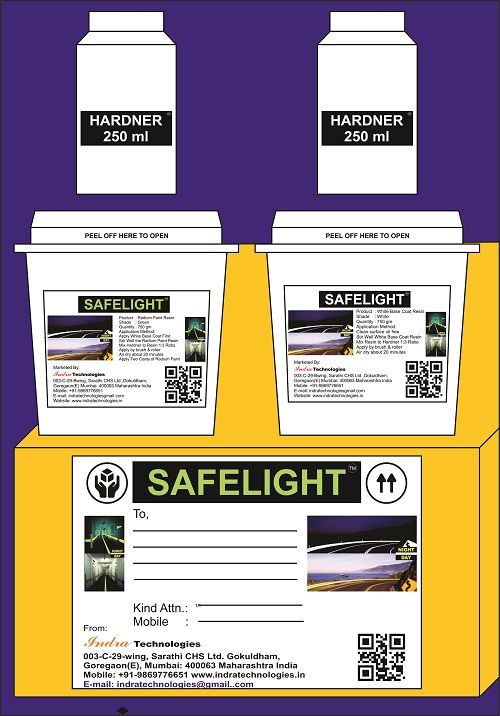

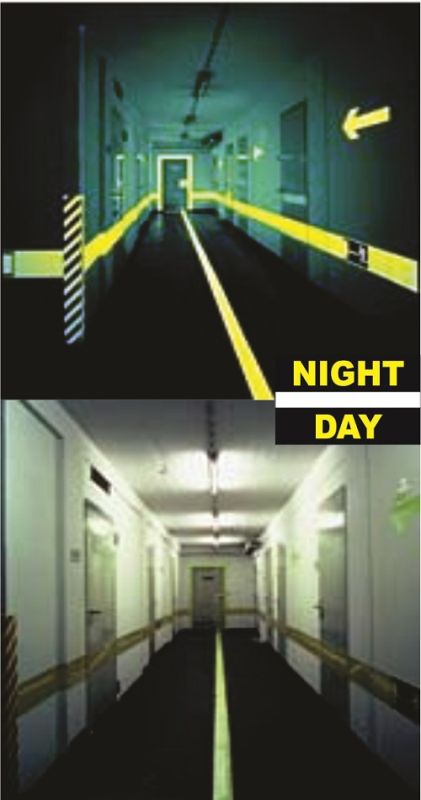

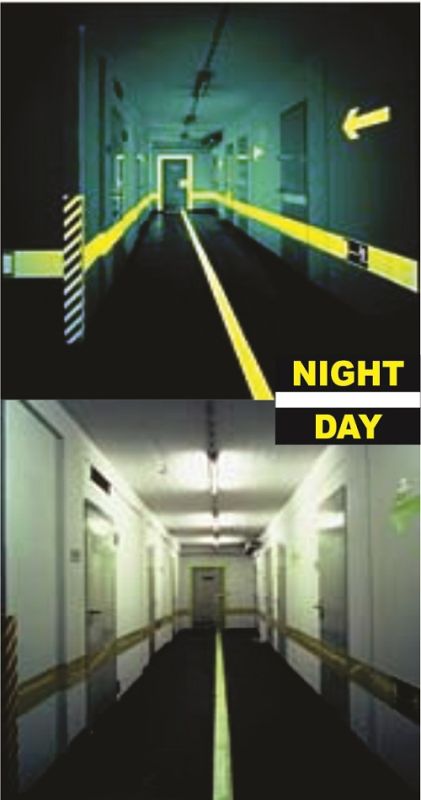

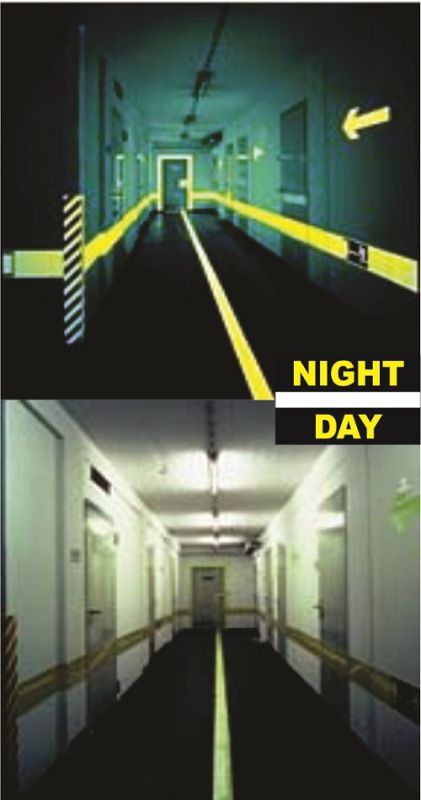

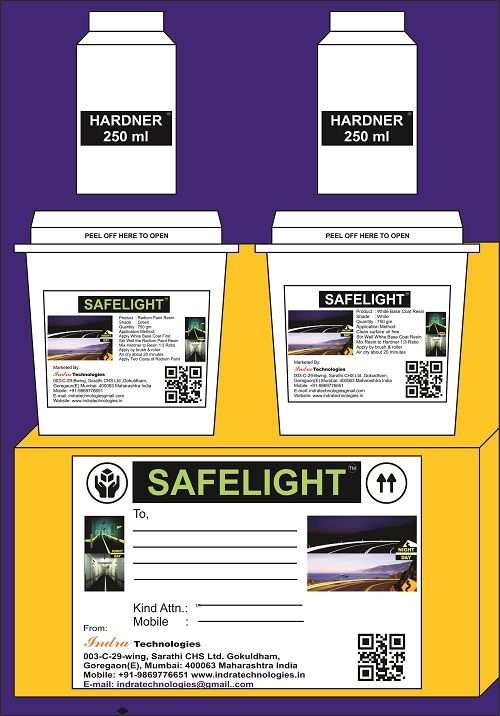

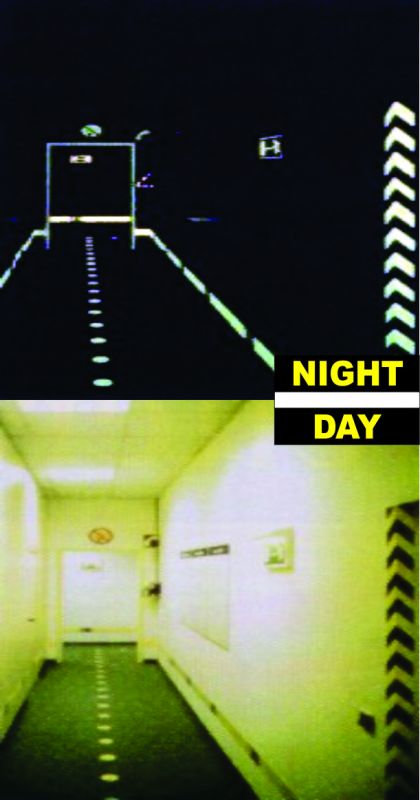

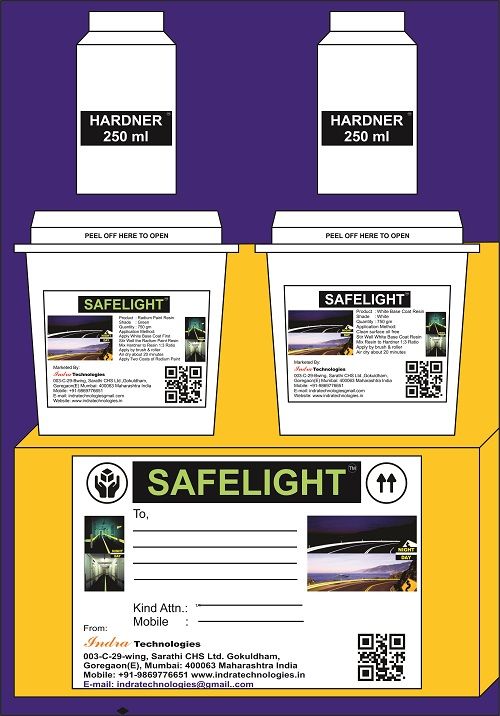

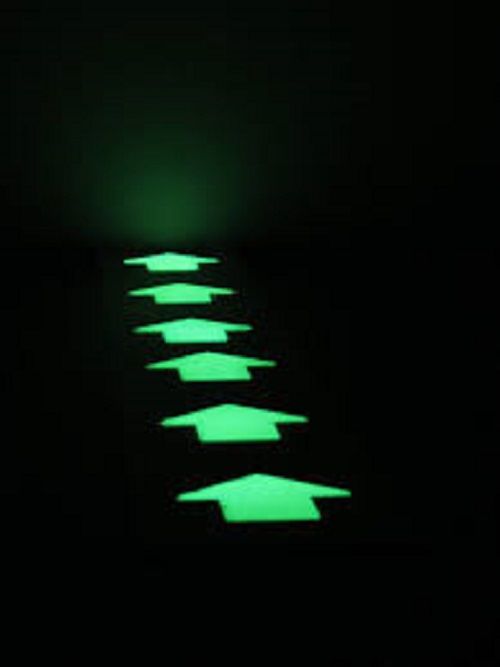

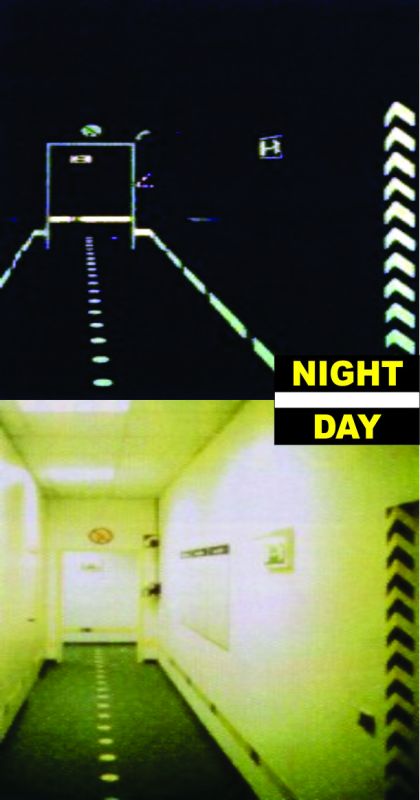

Radium Paint is a photoluminescent safety coating used for lane marking in power plants, chemical plants, textile units, and other industrial facilities. During emergencies like fire, flooding, or earthquake, when power failure causes blackout, the glowing lanes guide safe evacuation.

Special Feature-

Appears white in daylight

-

Glows green/blue in darkness

-

Charges under tube light in 3–4 hrs

-

Glows for 5–6 hrs in complete darkness

-

Pigments absorb surrounding light and get charged

-

In darkness, they emit visible radium green glow

-

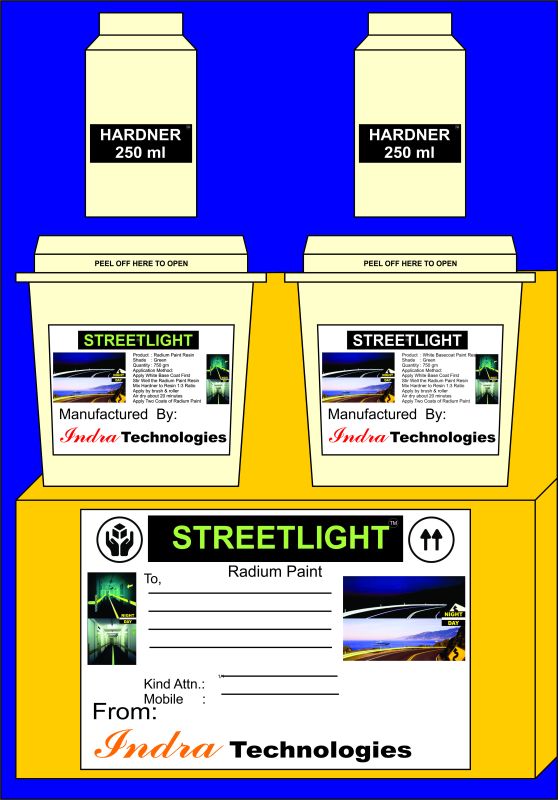

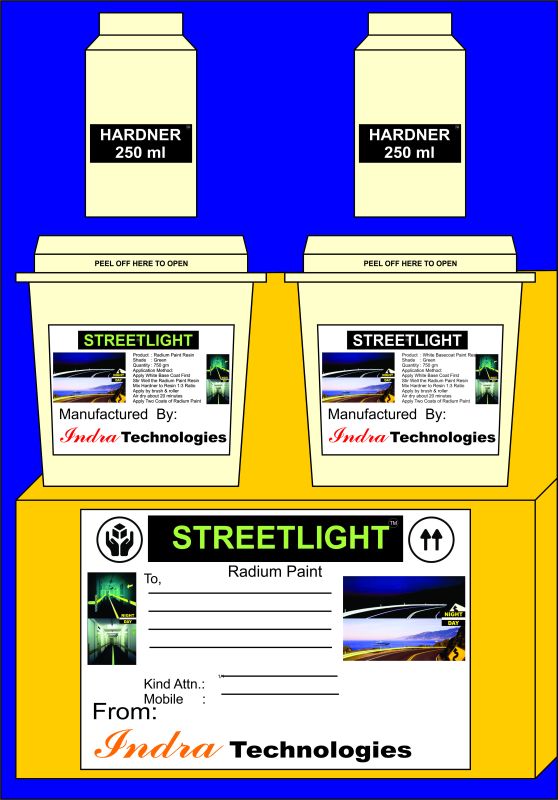

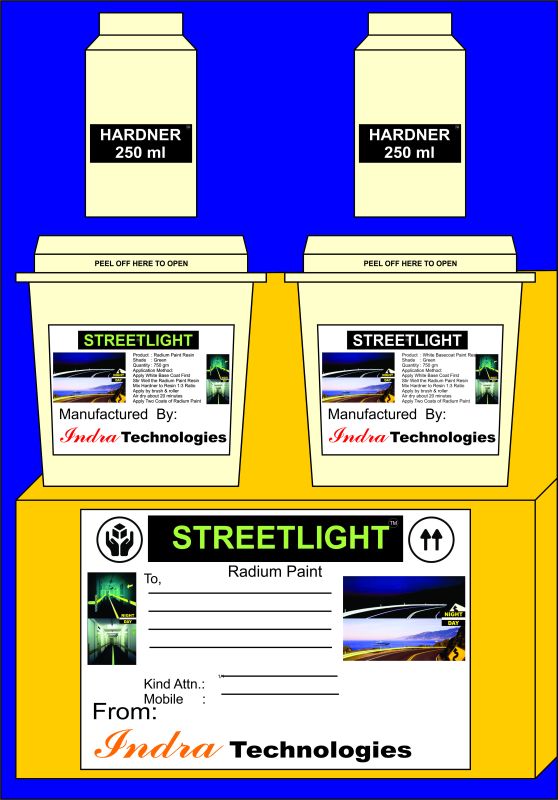

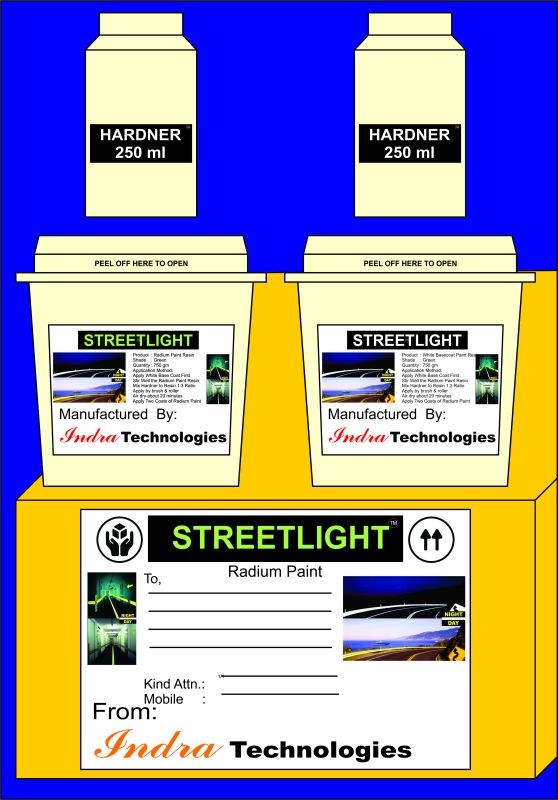

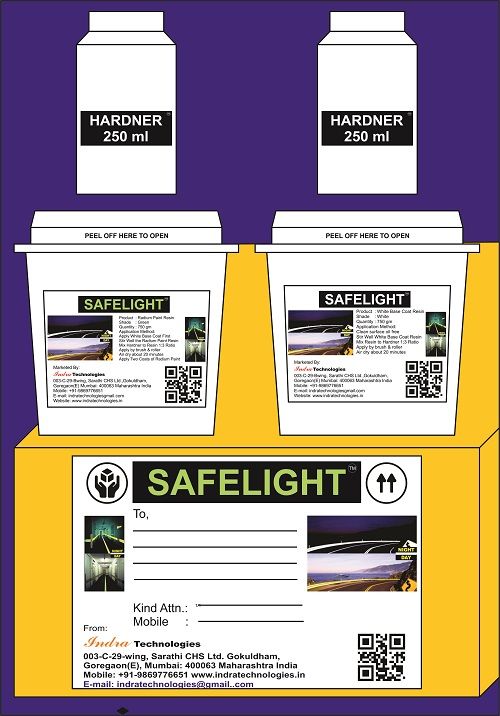

Mix resin & hardener in 3:1 ratio

-

Apply by spray painting within 1 hour

-

Basecoat of white polyurethane recommended for best results

-

1 liter, two-pack system

-

750 ml Resin + 250 ml Hardener

-

70 sq. ft. per liter

-

Shade: White in light, Green/Blue in dark

-

Brightness:

• 4500 mcd/m² @ 1 min

• 450 mcd/m² @ 10 min

• 27 mcd/m² @ 8 hrs -

Visibility limit: 0.32 mcd/m² (naked human eye)

-

Glow Duration: Up to 6 hrs after 3 hrs exposure

-

Night glow properties remain unchanged lifelong (unless physically damaged)

-

Type: Polyurethane resin-based

-

System: Two-pack (base + hardener, mixed before use)

-

Features: High gloss, UV resistant, non-yellowing, excellent flow

-

Finish: Smooth, glossy

-

Viscosity (base): 18–22 sec (Flow Cup No. 4 at 30°C)

-

Drying: Surface dry 20 min | Hard dry overnight | Full cure 7 days

-

Flash Point: Above 23°C

-

Application: Spray at 25–30 sec viscosity (stir during application)

-

Thinner: PU thinner

-

Mixing Ratio: Resin:Hardener (3:1 by volume)

-

Pot Life: 1 hour | Maturation: 20–30 min

-

Stoving: 120°C (15 min) or 60°C (40 min) after 20 min flash-off

-

Adhesion: Excellent on polyurethane topcoats

-

Flexibility: Passes ¼” mandrel

-

30% H₂SO₄ (24 hrs): Not affected

-

30% NaOH (30 hrs): Not affected

-

Petrol/Diesel (30 min): Not affected

-

Water (24 hrs): Not affected

-

Shelf Life: Several months (sealed, ambient conditions)

-

70 sq. ft. per liter

-

India: Mumbai, Maharashtra & all over India

-

International: Saudi Arabia, Dubai, Kuwait, Abu Dhabi, Middle East & Gulf

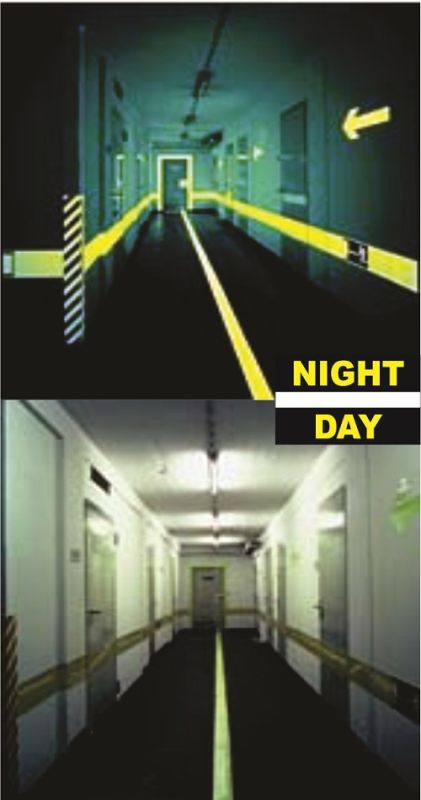

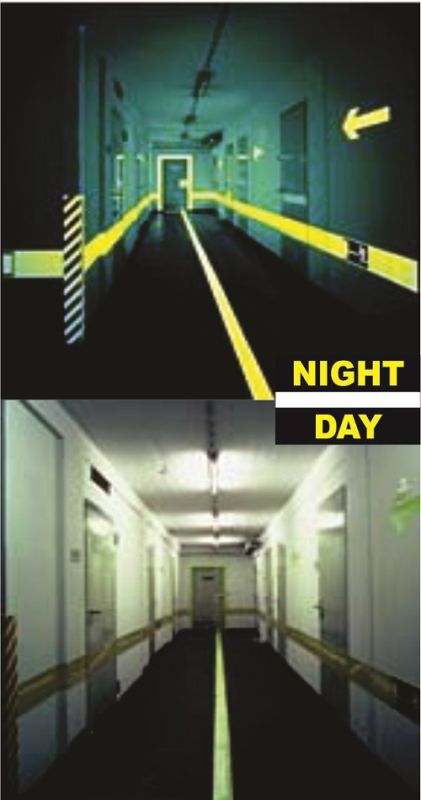

| Business Type | Manufacturer, Exporter, Supplier |

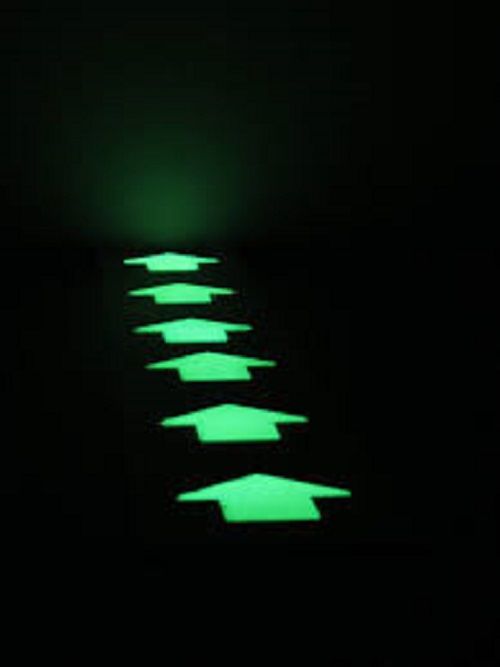

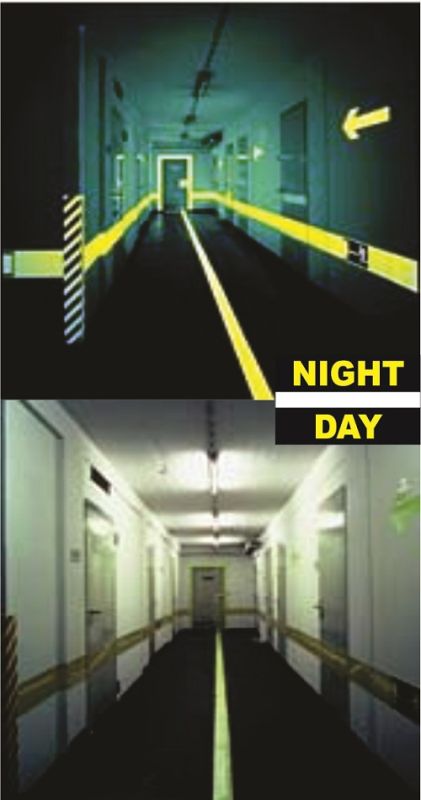

| Application | Emergency Evacuation Pathways |

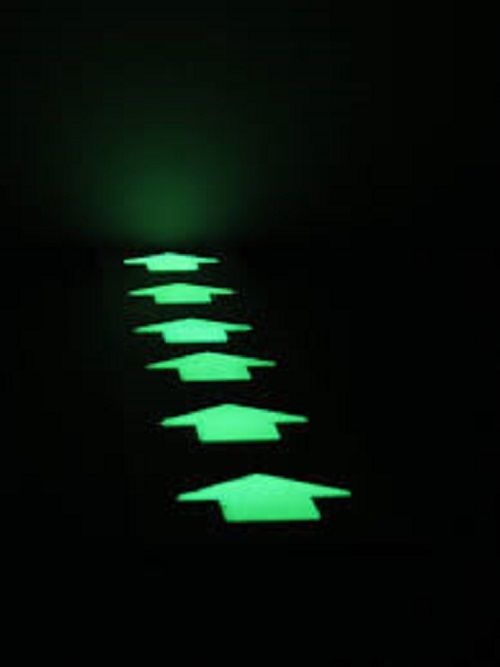

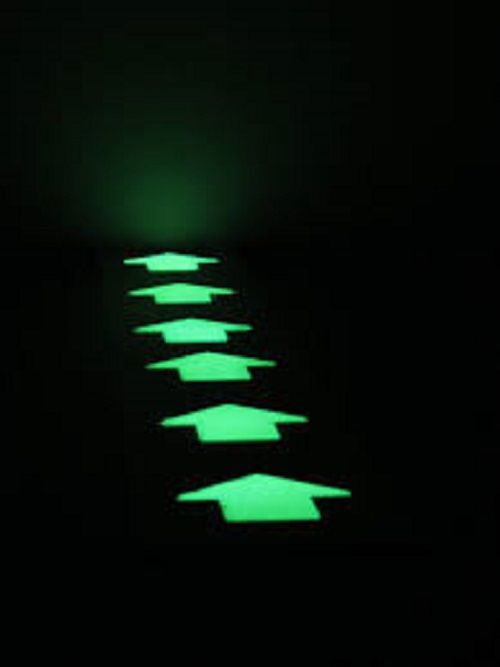

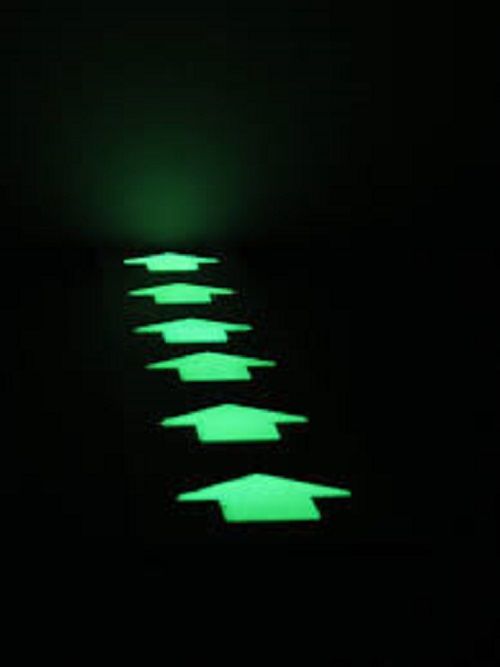

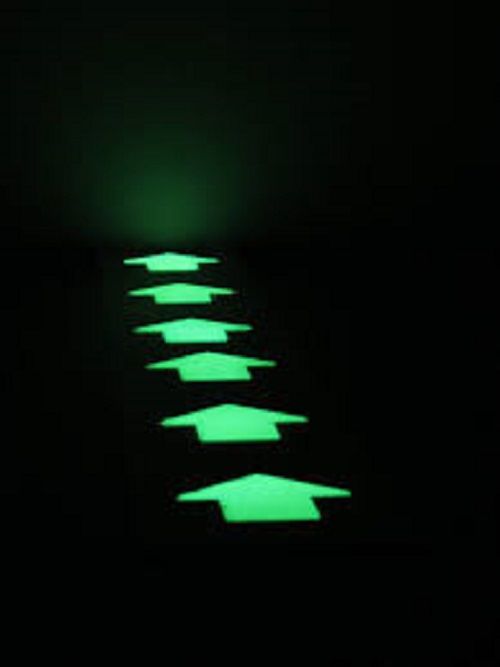

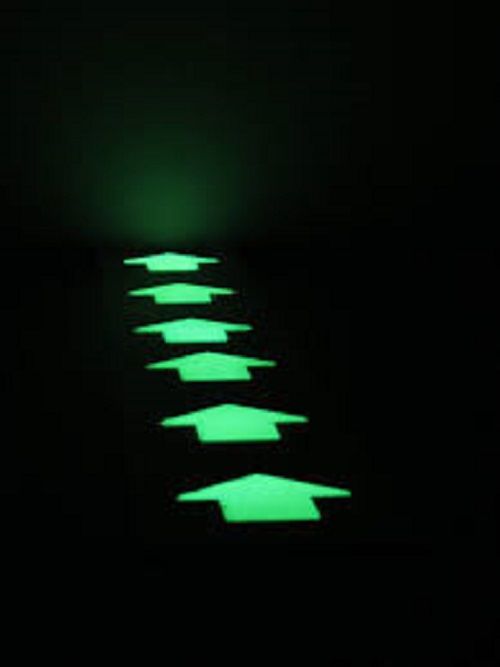

| Glow Color | Radium Green |

| Coverage | 70 Sq.ft./liter (standard) | 50 Sq.ft./liter (depending On Surface) |

| Brightness | 4500 Mcd/m² @ 1 Min | 450 Mcd/m² @ 10 Min | 27 Mcd/m² @ 8 Hrs |

| Visibility Limit | 0.32 Mcd/m² |

| Exposure | Needs ~3 Hrs Charging → Glows Up To 14 Hrs In Dark |

| Type | IG 6 Night Glow Lane Marking Paint |

| Packaging Type | 1 Liter (Two-pack System: Base + Hardener) |

| Product Code | ITV1 |

| Port | Mumbai |

| Payment Terms | L/C |

| Delivery Time | One week |

| Packaging Details | Two pack |

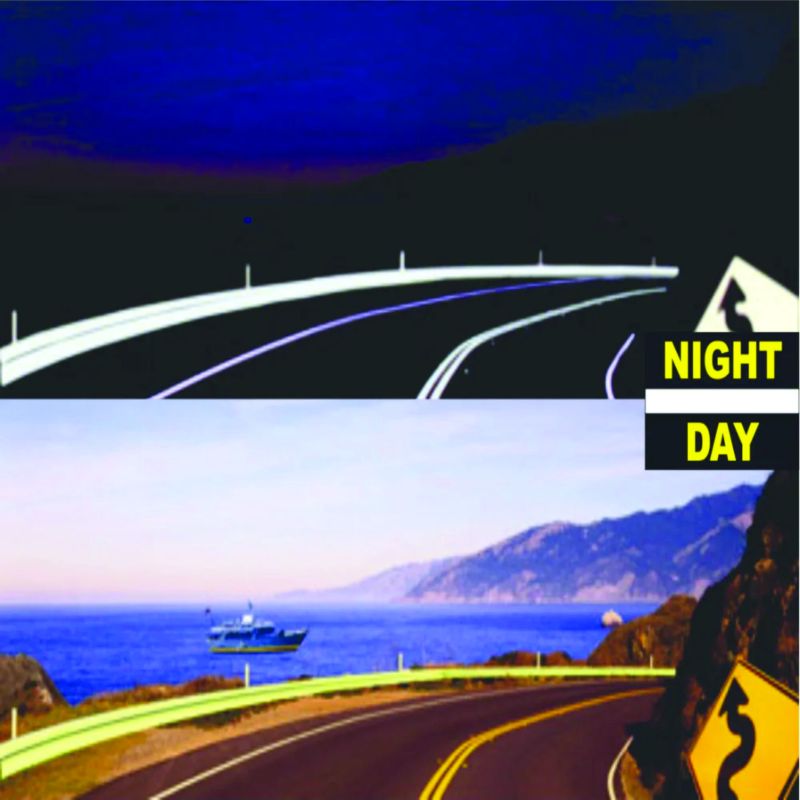

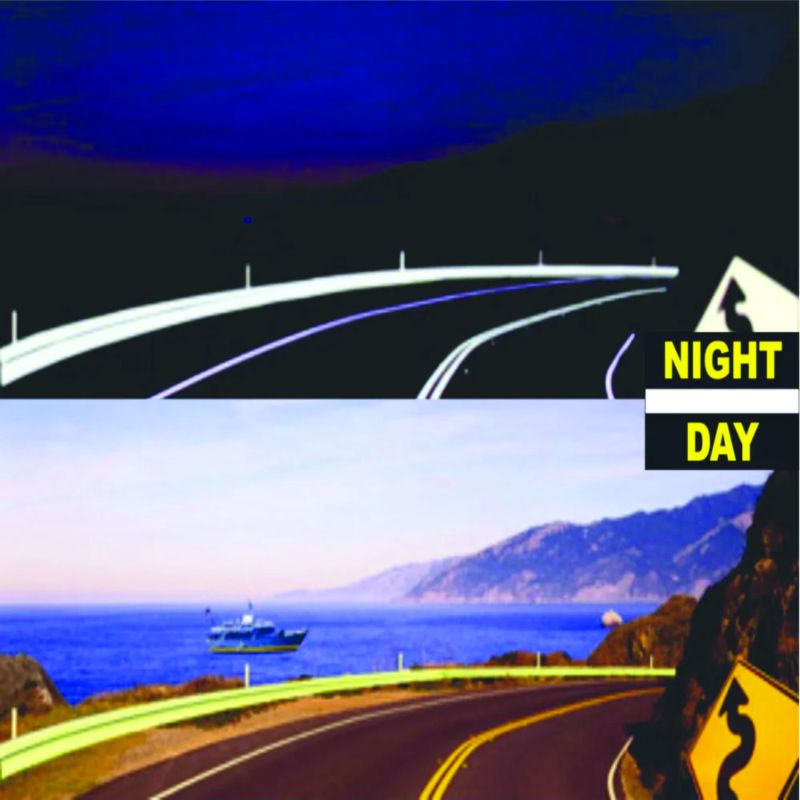

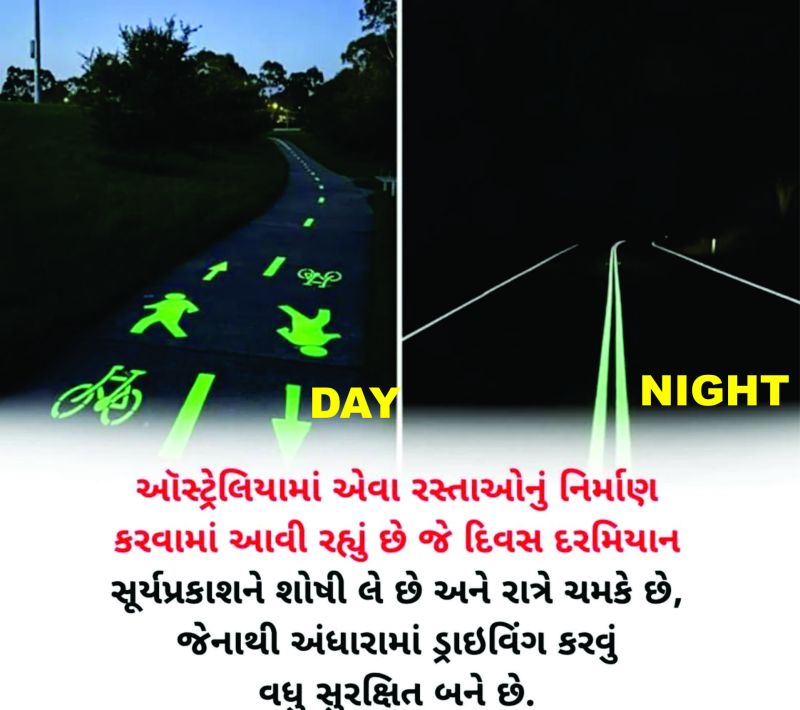

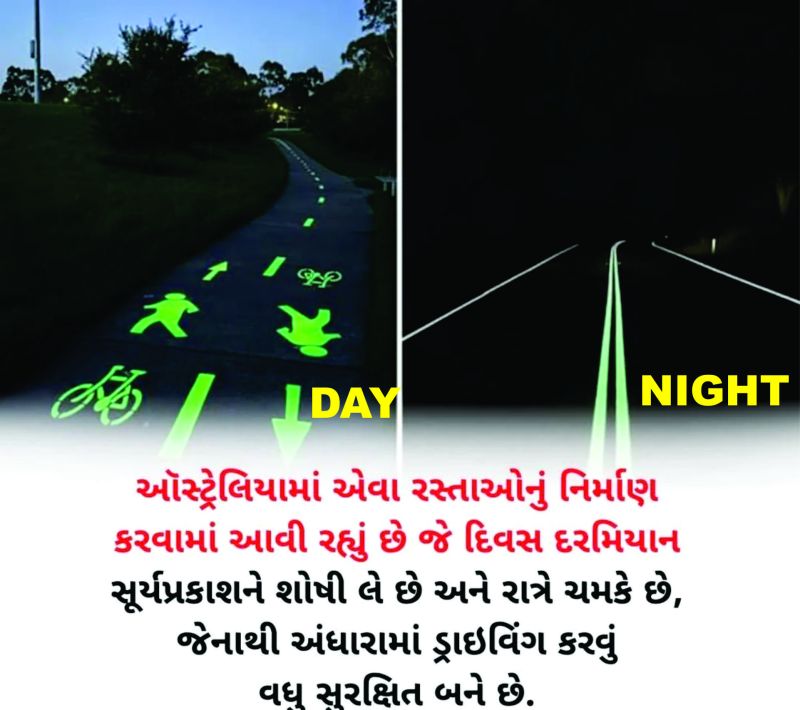

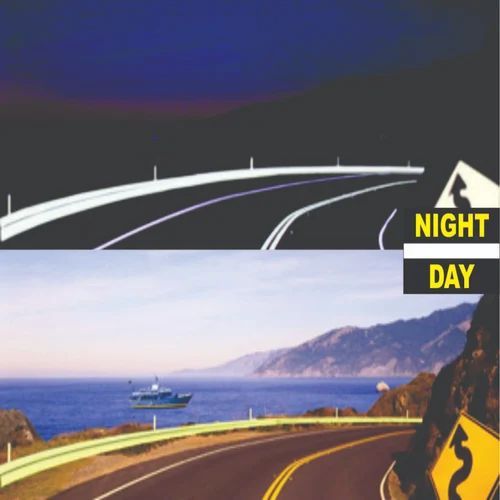

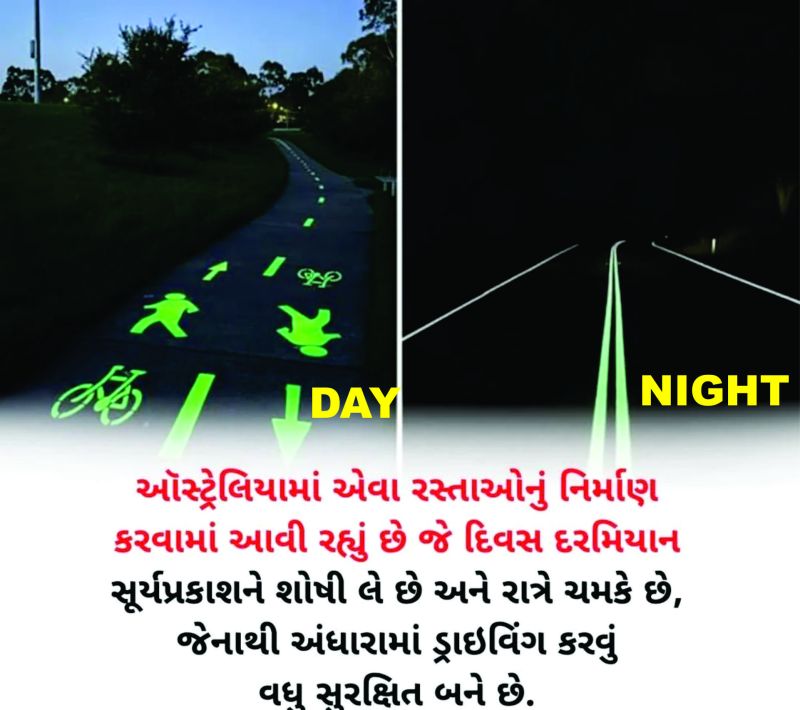

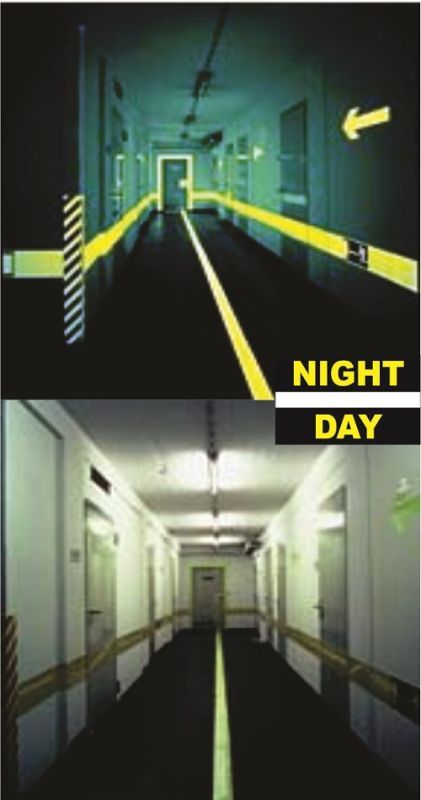

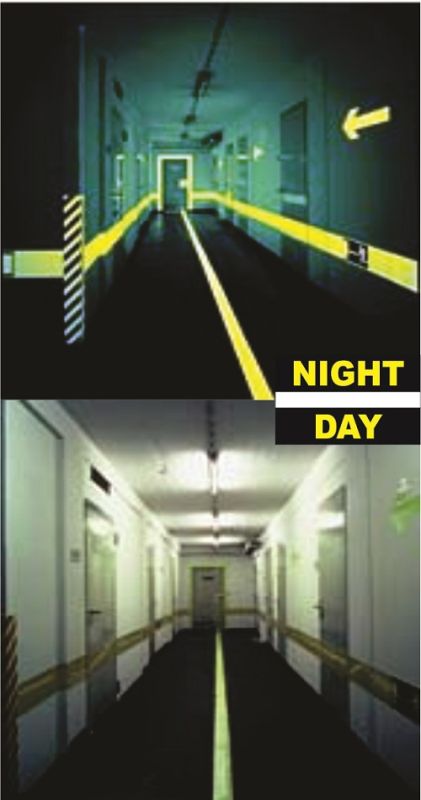

IG-6 Night Glow Lane Marking Paint is a premium-grade photoluminescent coating designed to improve road safety during nighttime and low-visibility conditions. Engineered with advanced IG-6 luminescent technology, this paint absorbs natural sunlight or artificial light during the day and glows automatically at night, ensuring bright and clear visibility of road lanes for up to 10–12 hours.

Most road accidents occur at night due to poor lane visibility and over-dependence on headlights. Unlike ordinary reflective paints, which require direct light to reflect, IG-6 Night Glow Lane Marking Paint continues to shine even in complete blackout conditions—making it a life-saving alternative to traditional streetlights and reflective coatings.

Key Features & Benefits-

High-Intensity Glow: Visible from distances up to 1 kilometer in darkness.

-

Headlight-Independent Safety: Works even if vehicle headlights fail.

-

Cost-Effective Substitute to Streetlights: Eliminates heavy streetlight installation, energy, and maintenance costs.

-

Durable & Long-Lasting: Withstands rain, dust, UV exposure, and heavy traffic load.

-

Eco-Friendly: No electricity, batteries, or generators required.

-

Long Service Life: Guaranteed glow performance for 5+ years without re-application.

-

National highways and expressways

-

City roads and rural lanes without streetlights

-

Pedestrian crossings and zebra markings

-

Curves, blind turns, and accident-prone zones

-

Parking areas, toll plazas, and flyovers

Conventional streetlight installation costs are extremely high—millions per kilometer in infrastructure, energy, and maintenance. In comparison, IG-6 Night Glow Lane Marking Paint provides the same visibility benefits at just a fraction of the cost, with zero power consumption and no maintenance burden.

Case Study: Highway Section in Madhya PradeshIn 2024, a 15 km highway stretch near Indore was prone to frequent accidents due to poor visibility and lack of adequate lighting. Authorities applied IG-6 Night Glow Lane Marking Paint across lane dividers and pedestrian crossings.

-

Result: Night-time accidents reduced by over 50% within six months.

-

Driver Feedback: Motorists reported that lanes were clearly visible even during headlight malfunctions and foggy nights.

-

Savings: The project saved approximately ₹12 crores by avoiding additional streetlight installations and energy bills.

This case shows how IG-6 Night Glow Lane Marking Paint is not just a coating, but a transformative solution for safer and more sustainable road infrastructure.

| Business Type | Manufacturer, Exporter, Supplier |

| Application | Road Marking Lane Marking Emergency Evacuation |

| Color | Greenish |

| Material | Luminescent Pigments |

| Type | Night Glow Paint |

| Brand Name | Streetlight |

| Other Names | Radium Paint, Night Glow Paint , Autoglow Paint, Phosphorescent Paint, Luminous Paint, Glow In Dark |

| Packaging Type | Bottle Or Tube |

| Drying Time | 6 Hours |

| Finish | Matte Finish |

| Product Code | ITV1 |

| Port | Mumbai |

| Payment Terms | L/C |

| Delivery Time | One week |

| Packaging Details | Two Pack |

IG-6 Night Glow Paint is a next-generation photoluminescent coating developed using advanced IG-6 technology to deliver long-lasting glow visibility for safety, industrial, and decorative applications. Unlike conventional reflective paints, which depend on direct light reflection, IG-6 Night Glow Paint absorbs natural daylight or artificial light and automatically glows in darkness for 10–12 hours, ensuring visibility even during complete blackout conditions.

This makes it a reliable and cost-effective substitute for electrical lighting systems, emergency lamps, and reflective coatings—offering both safety and energy savings.

Key Features & Benefits-

High-Performance Glow: Bright luminescence visible from long distances.

-

Headlight / Power-Independent: Works even during total power failure.

-

Durable & Long-Lasting: Resistant to rain, UV rays, dust, and chemical exposure.

-

Eco-Friendly: Requires no electricity, batteries, or backup power.

-

Multi-Surface Application: Can be applied on concrete, metal, wood, and plastics.

-

Long Life Guarantee: Maintains glow performance for 5+ years with minimal upkeep.

-

Road Safety: Lane markings, dividers, crash barriers, pedestrian crossings.

-

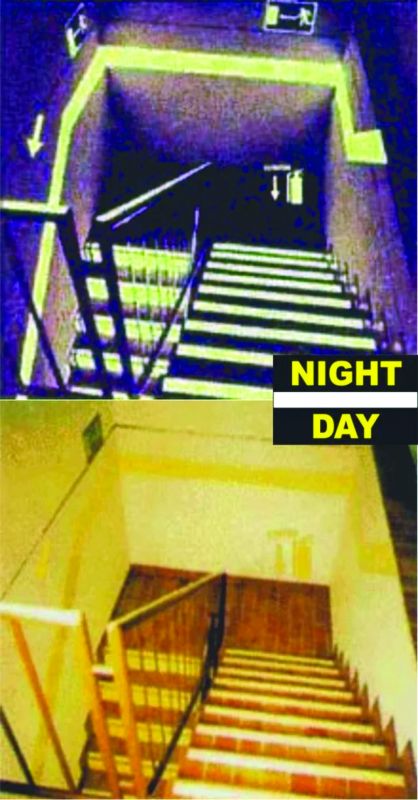

Industrial Safety: Escape routes, staircases, fire exits, machinery markings.

-

Tunnels & Mines: Guidance markings during blackouts or emergencies.

-

Aviation & Marine: Helipad markings, offshore platforms, ship decks.

-

Public Spaces: Metro stations, parking zones, bridges, malls.

-

Decorative Uses: Signboards, garden pathways, artistic designs.

Installing streetlights, emergency lamps, or backup generators involves huge capital, energy, and maintenance costs. In comparison, IG-6 Night Glow Paint provides one-time installation with zero recurring expense, making it one of the most economical long-term safety solutions.

Case Study: Metro Station Evacuation MarkingsIn 2024, a metro station in Delhi implemented IG-6 Night Glow Paint on staircases, exit signs, and platform edges as a pilot safety project.

-

Observation: During a simulated power failure, commuters were able to evacuate safely using glowing markings without any electrical backup.

-

Impact: Authorities recorded a 70% improvement in evacuation time, demonstrating how photoluminescent coatings enhance passenger safety.

-

Savings: The project avoided recurring energy and maintenance costs linked to emergency lamps.

This project proved that IG-6 Night Glow Paint is more than just a coating—it is a life-saving innovation that enhances safety while cutting costs.

| Business Type | Manufacturer, Exporter, Supplier |

| Color | Green,Blue |

| Type | Photoluminescent Paint |

| Brand Name | Streetlight |

| Duration Of Glow | 6 Hours |

| Key Features | Charges With Normal Light, Glows In Darkness (6 Hrs) |

| Industrial Applications | Emergency Evacuation Marking In Plants & Factories |

| Benefits | Provides Glowing Guidance In Power Failures, |

| Product Code | ITV1 |

| Port | Mumbai |

| Payment Terms | L/C |

| Delivery Time | One week |

IG-6 Night Glow Photoluminescent Phosphorescent Paint is an advanced safety coating formulated with high-grade strontium aluminate pigments under the IG-6 series. It is designed to absorb sunlight or artificial light and emit a strong, long-lasting glow in darkness for 10–12 hours continuously. Unlike conventional reflective paints, which only shine when headlights or external light sources hit them, this dual-action photoluminescent and phosphorescent paint remains visible even in complete blackout conditions.

This makes it a reliable, eco-friendly, and cost-effective solution for road safety, industrial safety, tunnels, mines, aviation, marine, and decorative applications.

Key Features & Benefits-

Photoluminescent + Phosphorescent Action: Stores energy during the day and glows automatically at night.

-

Long-Lasting Glow: Visibility of 10–12 hours after full charge.

-

High Intensity: Visible up to 1 km distance in open environments.

-

Headlight / Power-Independent: Works even without electricity or direct light reflection.

-

Weather Resistant: Withstands rain, UV rays, dust, and heavy traffic conditions.

-

Durable Performance: Service life of 5+ years with minimal maintenance.

-

Eco-Friendly: Requires no electricity, batteries, or generators.

-

Multi-Surface Application: Bonds well with concrete, asphalt, metal, wood, plastics, and composites.

-

Road & Transport Safety: Lane markings, dividers, crash barriers, pedestrian crossings.

-

Tunnels & Mines: Safety guidance during power failures and low-visibility conditions.

-

Industrial Safety: Fire exits, staircases, escape routes, machinery zones.

-

Aviation & Marine: Helipad markings, offshore platforms, ship decks, airport safety zones.

-

Public Infrastructure: Metro stations, bridges, subways, parking lots.

-

Emergency Preparedness: Disaster evacuation pathways in case of fire, earthquake, or blackout.

-

Decorative & Functional Use: Glow signboards, garden pathways, indoor and outdoor design projects.

Conventional lighting systems require high capital investment, continuous electricity, and regular maintenance. In comparison, IG-6 Night Glow Photoluminescent Phosphorescent Paint is a one-time application that provides years of performance with zero energy cost. It is especially beneficial for rural and remote locations where power availability is limited.

Case Study: Tunnel Safety Project in UttarakhandIn 2024, a 3 km highway tunnel in Uttarakhand faced frequent power failures, creating hazardous conditions for drivers. Authorities implemented IG-6 Night Glow Photoluminescent Phosphorescent Paint on lane markings, wall edges, and emergency exit signage.

-

Result: Glow markings remained visible for over 12 hours after daylight charging.

-

Impact: Accident risk reduced by over 60% in six months.

-

Savings: Eliminated dependence on costly backup generators and reduced lighting maintenance expenses.

-

Feedback: Drivers and emergency services reported higher confidence and safer navigation during blackouts.

This real-life case highlights how IG-6 Night Glow Photoluminescent Phosphorescent Paint is not just a paint but a life-saving innovation that combines safety, durability, and cost efficiency.

| Business Type | Manufacturer, Exporter, Supplier |

| Application | Improving Safety In Underground And Surface Coal Mines |

| Color | Glow In The Dark |

| Material | Europium-doped Strontium Aluminate, Polyurethane Resin |

| Type | Safety Radium Paint |

| Brand Name | Safelight |

| Other Names | Radium Paint, Night Glow Paint , Autoglow Paint, Phosphorescent Paint, Luminous Paint, Glow In Dark |

| Duration Of Glow | 10-12 Hours |

| Charge Time | 10-15 Mins |

| Operating Temperature | -10°C To 120°C |

| Surface Compatibility | Stone, Concrete, MS, GI, Painted Walls |

| Product Code | ITV1 |

| Port | Mumbai |

| Payment Terms | L/C |

| Delivery Time | One week |

IGT-17 Coal Mines Safety Radium Paint is a specially formulated photoluminescent coating developed for use in underground coal mines, where visibility and safety are critical. This advanced radium-based paint absorbs natural or artificial light and automatically glows in the dark for 10–12 continuous hours, ensuring that miners and workers can clearly see escape routes, safety signage, and equipment even during power failures or emergencies.

Unlike reflective paints that only shine when direct light falls on them, IGT-17 Radium Paint works independently of any external source, making it a vital safety tool in coal mines where blackout situations are frequent.

Key Features & Benefits-

High-Intensity Glow: Provides clear visibility in total darkness.

-

Independent of Power: Works without electricity, lamps, or batteries.

-

Safety-Oriented: Enhances guidance during mine emergencies such as fire, gas leakage, or collapse.

-

Durable & Long-Lasting: Resistant to dust, moisture, and extreme underground conditions.

-

Eco-Friendly: No energy consumption, no emissions.

-

Service Life: Effective glow performance for 5+ years with a single application.

-

Marking of escape routes, staircases, and pathways

-

Emergency exit signs inside underground tunnels

-

Hazard zone markings around pits, machinery, and explosives storage

-

Safety equipment marking (helmets, trolleys, shafts, barriers)

-

Guidance stripes along tunnel walls and ceilings

Coal mines spend heavily on emergency lamps, battery-operated lights, and generators to ensure worker safety. These systems are costly to maintain, prone to failure, and need constant replacement. In comparison, IGT-17 Coal Mines Safety Radium Paint offers a one-time, low-maintenance solution with zero recurring electricity or backup power costs.

Case Study: Underground Coal Mine – Dhanbad, JharkhandIn 2024, a major coal mine in Dhanbad implemented IGT-17 Coal Mines Safety Radium Paint on escape routes, shaft edges, and exit signs.

-

Observation: Even during a simulated power outage, pathways remained visible for over 10 hours, ensuring safe evacuation.

-

Impact: Safety drills showed a 40% reduction in evacuation time, improving survival chances during emergencies.

-

Savings: Significant reduction in battery lamp usage and backup generator costs.

-

Feedback: Workers reported higher confidence while working underground, and safety inspectors praised it as an innovative, life-saving technology.

This project proved that IGT-17 Coal Mines Safety Radium Paint is not just a coating but a critical safety innovation for one of the world’s most hazardous industries.

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Photoluminescent Coating |

| Color | Yellow-Green |

| Application | Enhance Visibility And Safety Of Trailers And Semi-trailers During Night Driving,Brush, Roller, Or Airless Spray |

| Glow Duration | 10-12 Hrs |

| Charge Time | 10-15 Mins |

| Drying | 6-8 Hrs |

| Film Thickness | 60-80 Microns Per Coat |

| Operating Temperature | -10°C To 120°C |

IGT-42 is a high-performance photoluminescent coating designed to enhance visibility and safety of trailers and semi-trailers during night driving, low-light conditions, or parked situations. Ideal for logistics fleets, container carriers, flatbeds, fuel tankers, and chemical transport vehicles.

Key Features-

Glows for 10–12 hrs after 10–15 mins charging (sunlight, streetlight, headlights)

-

Uses Europium-activated Strontium Aluminate pigments (non-toxic, non-radioactive)

-

Functions as a passive light source—no wiring, electricity, or batteries required

-

Improves vehicle outline detection and reduces collision risk at night

-

UV-stable, weather-resistant, suitable for outdoor exposure

-

VOC compliant, safe for transport sector usage

-

Rear and side panels of trailers and containers

-

Outline marking of flatbed semi-trailers and chassis

-

Fuel, milk, and chemical tankers

-

Refrigerated trailers and cargo units

-

Parked trailers in yards & terminals

-

Hazardous goods carriers during night transit

-

Improves safety by highlighting trailer boundaries

-

Works even if electrical lights fail

-

Reduces risk of accidents on highways and rural roads

-

Long-lasting, cost-effective alternative to powered lights or reflectors

-

Suitable for urban, industrial, highway, and remote routes

-

Type: 2-part polyurethane resin + industrial hardener

-

Glow Duration: 10–12 hrs

-

Charge Time: 10–15 mins (sunlight/artificial light)

-

Application: Brush, roller, or airless spray

-

Drying: Touch dry 25 mins | Full cure 6–8 hrs

-

Film Thickness: 60–80 microns per coat (2 coats recommended)

-

Colors: Yellow-Green / Blue-Green

-

Surface Compatibility: MS, GI, aluminum, FRP, painted metal

-

Operating Temperature: -10°C to 120°C

-

Environmental Safety: VOC compliant

-

A logistics company applied IGT-42 on chemical tankers operating between Gujarat and Maharashtra.

-

Glow outlines improved visibility in fog and low-light highways, reducing collisions.

-

Enhanced compliance with road safety regulations.

-

Fleet owners & logistics service providers

-

Fuel, milk, and chemical transporters

-

Container carriers & contractors

-

Military trailers & agricultural machinery trailers

-

Road safety consultants & regulatory compliance projects

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Strontium Aluminate Pigments |

| Application | Improves Visibility, Worker Safety, And Evacuation |

| Type | Photoluminescent Coating |

| Brand Name | Safelight |

| Color | Green In The Dark |

| Other Names | Radium Paint, Night Glow Paint , Autoglow Paint, Phosphorescent Paint, Luminous Paint, Glow In Dark |

| Glow Duration | 10-12 Hours |

| Adhesion | High, Solvent-resistant |

| Drying Time | 6-8 Hrs |

| Glow Colors | Yellow-Green |

| Heat Resistance | Up To 110°C |

| Product Code | ITV1 |

| Port | Mumbai |

| Payment Terms | L/C |

| Delivery Time | One week |

IGT-49 Safelight Night Glow Paint is a high-performance photoluminescent safety coating engineered with advanced IGT-49 formulation to provide long-lasting glow visibility in darkness and low-light conditions. This paint absorbs natural or artificial light and automatically emits a bright glow for 10–12 hours, ensuring continuous visibility even in blackout situations.

Unlike ordinary reflective paints that rely solely on headlights or external illumination, IGT-49 Safelight Paint works independently, making it a life-saving solution for emergency routes, industrial safety, and public infrastructure.

Key Features & Benefits-

High Glow Intensity: Provides clear visibility from long distances in total darkness.

-

Energy-Free Illumination: Works without electricity, batteries, or generators.

-

Reliable Safety Tool: Critical for evacuation during fire, earthquake, power failure, or accidents.

-

Durable & Long-Lasting: Withstands weather, UV exposure, and heavy usage.

-

Eco-Friendly: No emissions, no energy costs, and minimal maintenance.

-

Multi-Surface Application: Suitable for concrete, metal, wood, plastics, and composites.

-

Service Life Guarantee: Maintains glow performance for 5+ years.

-

Emergency Safety: Exit routes, staircases, fire exit signs, evacuation pathways.

-

Road & Transport: Lane markings, zebra crossings, crash barriers, pedestrian zones.

-

Industrial Use: Factories, warehouses, and hazardous zones requiring safety signage.

-

Public Infrastructure: Metro stations, airports, tunnels, parking lots, subways.

-

Disaster Preparedness: Safe navigation during natural disasters like earthquakes, floods, or cyclones.

-

Specialized Areas: Hospitals, schools, high-rise buildings, and defense establishments.

Installing emergency lights, reflective signage, or backup power systems involves high costs of installation, electricity, and maintenance. In comparison, IGT-49 Safelight Night Glow Paint offers a one-time economical solution, ensuring long-term safety visibility with zero energy expense.

Case Study: Metro Station Safety Upgrade – MumbaiIn 2024, a busy metro station in Mumbai faced challenges during power outages, creating panic among commuters. Authorities applied IGT-49 Safelight Night Glow Paint on staircases, wall edges, and exit routes.

-

Observation: During a simulated blackout, evacuation was smooth as all routes remained clearly visible for over 10 hours.

-

Impact: Passenger safety improved, and evacuation time was reduced by 65%.

-

Cost Savings: Avoided large recurring electricity bills for emergency lighting.

-

Feedback: Both commuters and safety officials praised the paint as a critical safety enhancement.

This real-life project demonstrated that IGT-49 Safelight Night Glow Paint is not just a coating, but a vital safety solution for modern infrastructure.

| Business Type | Manufacturer, Exporter, Supplier |

| Application | Exit Door & Evacuation Route Marking Etc. |

| Color | Yellow-Green |

| Type | Luminescent Paint |

| Material | Dual-component Epoxy Resin + Hardener |

| Glow Duration | 10-12 Hrs |

| Thickness | 80-100 Microns (2 Coats) |

| Drying Time | 8-10 Hrs |

| Shelf Life | 12 Months |

IGT-59 Luminescent Paint for Cosmetic Manufacturers

Specially engineered photoluminescent safety coating for cosmetic & personal care production facilities. Provides non-electric glow-in-the-dark guidance in production areas, cleanrooms, packaging units & storage zones. 👉 Effective substitute for Golden Yellow Lane Marking paint.

Key Features

-

Photoluminescent – glows 10–12 hrs after light exposure (15–30 mins charge)

-

Contains high-grade strontium aluminate pigments (non-toxic, non-radioactive)

-

VOC-free, odorless, safe for GMP-regulated facilities

-

Chemical & solvent resistant – compatible with cosmetic raw materials

-

Works during blackouts, fire, or power failures – no electricity required

-

Quick application – brush, roller, or spray

Applications in Cosmetic Facilities

-

Exit door & evacuation route marking

-

Emergency equipment: eyewash stations, fire extinguishers, hydrants

-

Pathway & edge markings in filling/formulation rooms

-

Stair edges, pallet zones & lifts

-

Cleanroom zone demarcation

-

HVAC duct & control panel borders

-

QC labs & raw material storage areas

Core Benefits

-

Maintains visibility in blackout/fire/power outage

-

Safe for hygiene-sensitive areas (skincare, haircare, makeup, fragrance units)

-

Zero power or battery backup needed

-

Resistant to fuels, solvents & cleaning agents

-

Fast drying & strong adhesion on epoxy, RCC, SS, aluminum, tiles

-

Meets ISO, GMP & EHS protocols

Technical Overview

-

Type: Dual-component epoxy resin + hardener

-

Glow Duration: 10–12 hrs

-

Thickness: 80–100 microns (2 coats)

-

Colors: Yellow-Green (std.), Aqua Blue (opt.)

-

Drying Time: 30–40 mins (surface dry); 8–10 hrs (full cure)

-

Surface Compatibility: Epoxy floors, PU-coated walls, SS panels, tiles

-

Shelf Life: 12 months (store cool, dry)

-

Environmental Safety: VOC-free, odorless, RoHS compliant

Example Use Case

-

A Mumbai skincare manufacturer applied IGT-59 on walkways, exits & safety zones

-

During a power outage, 120+ employees evacuated safely using glowing paths

-

Integrated into permanent safety signage system afterward

Ideal For

-

Skincare, haircare & makeup plants

-

Fragrance & essential oil factories

-

Face mask & cosmetic wipes packaging units

-

Cosmetic R&D & QC laboratories

-

Warehouses storing perfumes, lotions, sensitive raw materials

| Business Type | Manufacturer, Exporter, Supplier |

| Application | Helipad Marking |

| Color | Radium Yellow |

| Material | Acrylic |

| Type | Paint |

| Brand Name | Indra Technologies |

| Other Names | Radium Paint, Night Glow Paint , Autoglow Paint, Phosphorescent Paint, Luminous Paint, Glow In Dark |

| Packaging Type | Can |

| Finish | Glossy |

| DryingTime | 1 Hour |

| Coverage | 150-200 Square Feet Per Gallon |

| SuitableFor | Outdoor Use |

| Product Code | ITV1 |

| Port | Mumbai |

| Payment Terms | L/C |

| Delivery Time | One week |

| Packaging Details | Two pack |

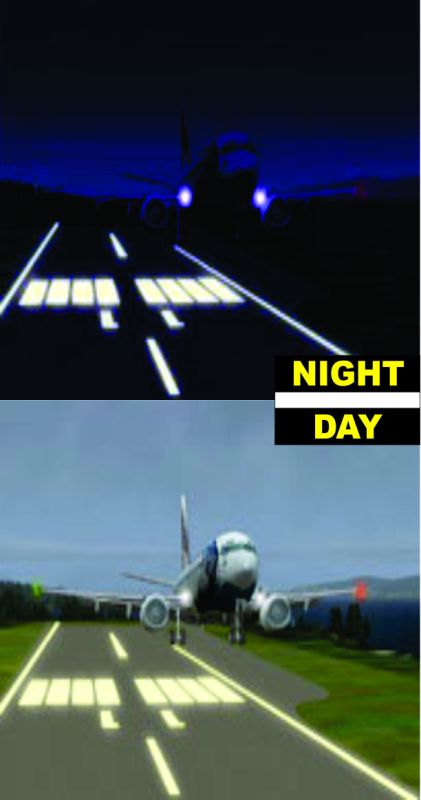

Radium Helipad Marking Paint is a high-performance photoluminescent coating developed to ensure maximum visibility and safety for helipad operations during nighttime and low-light conditions. Unlike ordinary reflective paints that depend solely on external light sources, this advanced radium-based paint absorbs natural daylight or artificial light and glows brightly in the dark, ensuring clear visibility of helipad markings even during power failures or emergencies.

Helipad markings are critical for safe aircraft landing and take-off. Conventional paints often fade quickly or fail to provide visibility in blackout situations, posing a serious risk. Radium Helipad Marking Paint provides consistent, long-lasting glow visibility for over 10–12 hours, making it an essential safety solution for both civilian and defense aviation facilities.

Key Features & Benefits-

High Glow Intensity: Clear visibility of helipad markings up to 1 km away at night.

-

Power-Free Illumination: Works without electricity, batteries, or backup lights.

-

Safety Assurance: Enhances pilot orientation and landing accuracy during poor visibility.

-

Durable & Weatherproof: Resistant to UV rays, rain, dust, jet blast, and heavy foot traffic.

-

Long Life Guarantee: Provides more than 5 years of glow performance with no recurring cost.

-

Eco-Friendly & Cost-Effective: Zero energy consumption and minimal maintenance.

-

Hospital emergency helipads

-

Commercial and private helipads

-

Military and defense helipads in remote zones

-

Offshore helipads on oil rigs and ships

-

Temporary disaster relief landing zones

Installing permanent lighting systems for helipads requires high capital investment, energy consumption, and maintenance. In comparison, Radium Helipad Marking Paint offers a one-time economical solution, guaranteeing night visibility and reducing dependency on complex lighting infrastructure.

Case Study: Emergency Hospital Helipad in RajasthanIn 2023, a hospital in Rajasthan upgraded its rooftop helipad with Radium Helipad Marking Paint to ensure safe emergency landings during power outages.

-

Implementation: The "H" symbol, landing circle, and boundary markings were coated with radium paint.

-

Results: During a sudden power failure, the helipad remained visible for over 10 continuous hours, enabling a safe night landing of an emergency air ambulance.

-

Feedback: Hospital authorities and pilots reported higher confidence in night operations and reduced dependency on costly lighting backup systems.

This real-life example proves that Radium Helipad Marking Paint is not just a coating, but a vital life-saving innovation for aviation safety.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Streetlight |

| Material | Pu based |

| Color | Radium Green in Dark & White in Daylight |

| Condition | New |

| Application | Crash Barrier |

| Type | Radium Paint |

| Packaging Type | Can |

| Finish | Glossy |

| Size | 1 Liter |

| Weather Resistance | Yes |

| Application Method | Brush Or Spray |

| Drying Time | 1 Hour |

| Product Code | ITV1 |

| Port | Mumbai |

| Payment Terms | L/C |

| Delivery Time | One week |

| Packaging Details | Two pack |

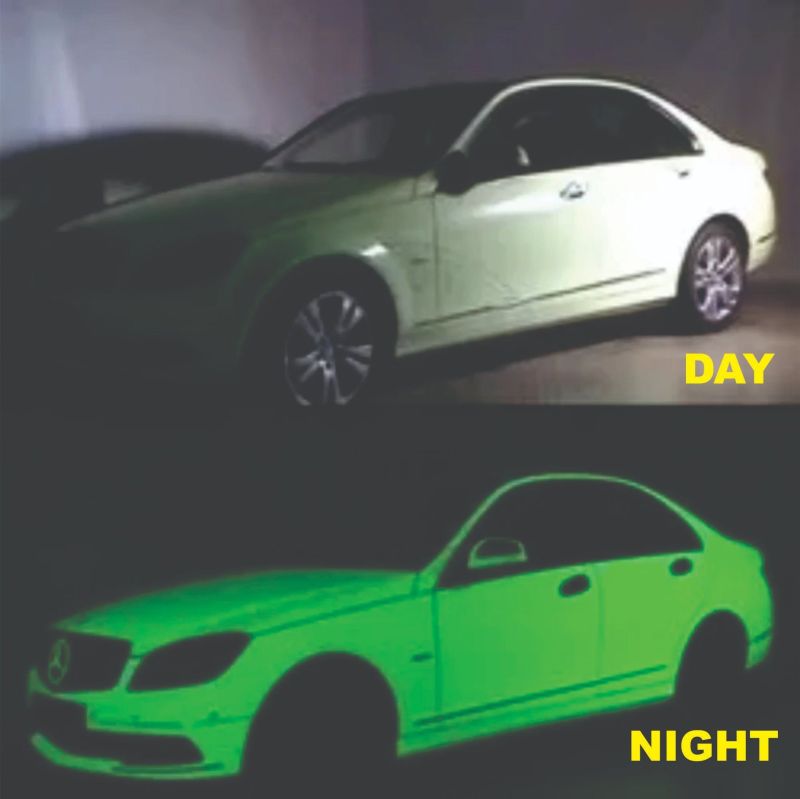

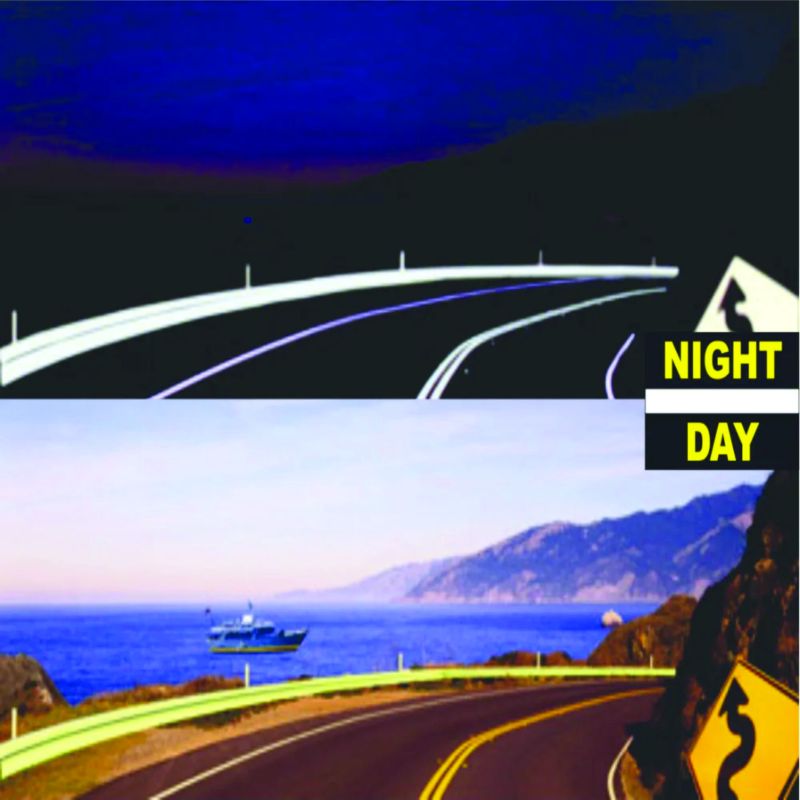

Radium Paint for Crash Barriers is an advanced photoluminescent coating developed to enhance road safety by ensuring high visibility of roadside crash barriers during night and low-light conditions. Most road accidents occur at night due to poor visibility of barriers at curves, flyovers, and highways. Traditional reflective paints are only visible when vehicle headlights directly fall on them. In contrast, our radium paint absorbs natural sunlight or artificial light during the day and glows brightly in the dark, offering round-the-clock visibility.

Why Radium Paint for Crash Barriers?Crash barriers are critical safety devices designed to reduce impact severity during accidents, but if they are not visible, their effectiveness is compromised. Radium Paint provides clear night visibility of barriers from a distance of up to one kilometer, helping drivers identify road boundaries and obstructions well in advance. This makes driving safer even when headlights malfunction or visibility is poor due to fog, rain, or dust.

Key Features & Benefits:-

High-Intensity Glow: Provides bright luminescence without electricity.

-

Headlight-Independent: Visible even if headlights are dim or not working.

-

Cost-Effective Alternative: Reduces dependency on reflective sheets and streetlights.

-

Weather & Impact Resistant: Withstands harsh outdoor conditions and heavy traffic exposure.

-

Long-Term Durability: Effective for 5+ years with no energy or maintenance cost.

-

Eco-Friendly Solution: Requires no power, batteries, or generators.

-

Crash barriers on highways and expressways

-

Flyovers, bridges, and tunnels

-

Accident-prone curves and sharp bends

-

Mountain roads and rural highways

-

Construction zones and temporary safety barriers

In 2023, a 7 km stretch of NH-48 near Bharuch, Gujarat, faced repeated accidents due to low visibility of crash barriers on curves. Authorities applied Radium Paint for Crash Barriers across the section.

-

Result: Accident frequency at night dropped by 45% within 4 months.

-

Driver Feedback: Drivers reported that barriers were visible even in foggy and rainy nights, allowing more reaction time.

-

Savings: The project saved costs compared to installing additional streetlights or reflective signage, with zero energy expenditure.

This project proved that Radium Paint is not just a coating but a life-saving technology, offering a sustainable and economical solution for road safety.

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Photoluminescent Coating |

| Material | Polyurethane + Acid-Alkali Hardener |

| Application | Safety Markings For Refineries, Petrochemical Plants, And Storage Facilities |

| Glow Duration | 10-12 Hours |

| Resistance | Fuels, Acids, Vapors |

| Application Method | Brush Or Spray |

| Surface Compatibility | RCC, MS, GI, Epoxy |

| Drying Time | 6-8 Hrs |

IGT-14 Radium Paint is a photoluminescent, chemical- and solvent-resistant coating designed for refineries, petrochemical plants, and storage facilities. It glows for 10–12 hours after light exposure, ensuring safe visibility during blackouts, emergencies, or shutdowns—making it a superior alternative to Golden Yellow Lane Marking paint.

Key Features-

Long-lasting glow, zero power requirement

-

Resistant to fuels, acids, and vapors

-

Fast drying, easy brush or spray application

-

Works in high-temperature and explosive zones

-

Compatible with RCC, MS, GI, and epoxy surfaces

-

Emergency exits, stair edges, safety railings

-

Fire hydrants, hose reels, extinguishers

-

Walkways, tank farms, process zones

-

Electrical panels, gas manifolds, pipeline racks

-

System: 2-component polyurethane + acid-alkali hardener

-

Pigment: Non-toxic Strontium Aluminate

-

Coats: 2 × 60–80 microns

-

Drying: Touch-dry 25 min, full cure 6–8 hrs

IGT-14 is a zero-maintenance, glow-in-the-dark safety solution for hazardous oil & gas environments.

| Business Type | Manufacturer, Exporter, Supplier |

| Application | Suitable For Painting Tunnels And Dark Areas |

| Color | Green In The Dark |

| Material | Radium-based |

| Type | Paint |

| Brand Name | Streetlight |

| Other Names | Radium Paint, Night Glow Paint , Autoglow Paint, Phosphorescent Paint, Luminous Paint, Glow In Dark |

| Packaging Type | Can Or Bucket |

| Safety Information | Follow Safety Instructions For Radium-based Products |

| Product Code | ITV1 |

| Port | Mumbai |

| Payment Terms | L/C |

| Delivery Time | One week |

| Packaging Details | Two Pack |

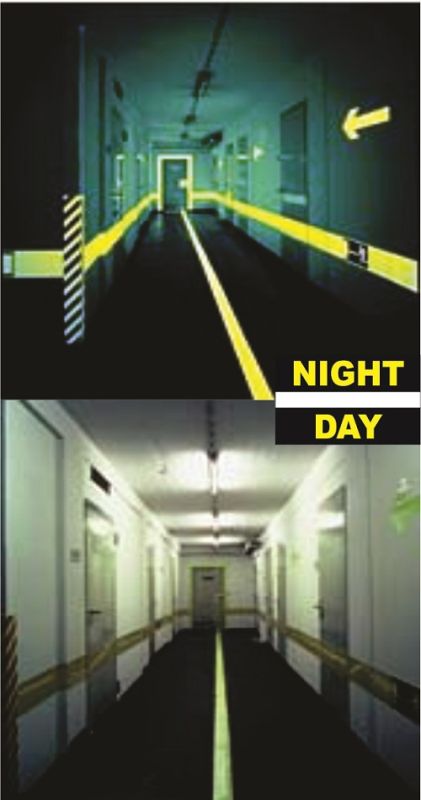

Radium Paints for Tunnels are specially engineered photoluminescent coatings designed to ensure maximum safety inside tunnels, underground passages, and low-light enclosures. Unlike conventional reflective paints that depend solely on headlights, radium paints absorb natural or artificial light during the day and glow automatically in the dark, providing reliable guidance to drivers and pedestrians when visibility is minimal.

Tunnels are among the most high-risk zones for accidents, especially during power failures, equipment breakdown, or vehicle headlight malfunctions. With Radium Paints for Tunnels, lane markings, crash barriers, walls, and emergency exits remain clearly visible 24x7, helping prevent collisions and enabling safe evacuation in emergencies.

Key Features & Benefits-

Self-Luminous Performance: Glows brightly for 10–12 hours after light absorption.

-

Power-Free Illumination: No need for electricity, batteries, or backup generators.

-

Critical Safety Tool: Enhances tunnel navigation and visibility in blackout situations.

-

Durable & Resistant: Withstands heavy traffic, moisture, exhaust gases, and dust.

-

Eco-Friendly & Cost-Saving: No recurring power or maintenance costs.

-

Long Life Guarantee: Provides effective glow performance for 5+ years.

-

Road tunnels on highways and expressways

-

Metro rail tunnels and underground corridors

-

Mining tunnels and industrial underground passages

-

Pedestrian underpasses

-

Escape routes, emergency exit signs, and fire safety markings inside tunnels

Installing artificial lighting inside tunnels involves high setup, electricity, and maintenance costs. In contrast, Radium Paints for Tunnels offer a one-time economical solution that ensures visibility during both normal and emergency conditions, with zero energy consumption and no maintenance burden.

Case Study: Mountain Tunnel in Himachal PradeshIn 2024, a 2.5 km mountain tunnel faced frequent power outages, making navigation difficult and unsafe for motorists. Authorities implemented Radium Paints on lane markings, crash barriers, and emergency exit signage.

-

Observation: Even during power failures, road lanes and exit routes glowed clearly for more than 10 hours.

-

Impact: Accident risk reduced by over 55% in the first six months of use.

-

Savings: Authorities saved significant costs by reducing dependency on diesel generators and backup lights.

-

User Feedback: Drivers felt more confident while crossing the tunnel, and emergency services praised the improved visibility.

This case demonstrates that Radium Paints for Tunnels are not just an economical coating but a critical life-saving solution for modern infrastructure.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Safelight |

| Material | Radium-based paint |

| Color | Green In The Dark |

| Application | Emergency Evacuation Pathways |

| Style | Two pack |

| Abrasive Grain Sizes | 56 microns |

| Type | Night Glow Paint |

| Other Names | Radium Paint, Night Glow Paint , Autoglow Paint, Phosphorescent Paint, Luminous Paint, Glow In Dark |

| Product Code | ITV1 |

| Port | Mumbai |

| Payment Terms | L/C |

| Delivery Time | One week |

Safelight Radium Paint for Aerospace & Airplane Industry In the aerospace and aviation sector, Safelight Radium Paint represents a next-generation solution for safety markings, instrumentation visibility, and emergency guidance systems on aircraft and aerospace structures. Designed to absorb ambient light and emit a bright glow in darkness, this photoluminescent paint offers unmatched reliability in critical environments — from cockpit instruments and control panels to external fuselage markings, landing gear indicators, cargo bay signs, and emergency exit pathways. ✈️ Role in Aerospace Safety Aerospace and aircraft systems operate under extreme conditions — rapid altitude changes, low-visibility night flights, power failures, and harsh weather. In such scenarios, Safelight Radium Paint acts as a passive, fail-safe illumination tool, continuing to glow even in total darkness without requiring any power source, wiring, or maintenance. This capability is vital for: Cockpit Instrumentation: Ensuring visibility of dials, switches, and indicators even during electrical failures. Cabin Safety: Highlighting exit routes, floor proximity escape paths, and emergency signage. Exterior Markings: Enhancing visibility of landing gear locks, access panels, propeller tips, and refuelling points during night operations. Maintenance Zones: Clearly identifying safety zones and critical maintenance points on the tarmac or in hangars. 🛰️ Modern Compliance & Regulatory Alignment Historically, radioactive radium-based paints were used in aircraft instruments. However, due to safety concerns and long-term radioactive risks, modern aviation regulators strictly control or prohibit their use. Safelight Radium Paint uses advanced, non-radioactive photoluminescent technology compliant with global safety and certification standards: FAA (Federal Aviation Administration, USA): Approves non-radioactive photoluminescent materials for emergency exit signage and escape path lighting under 14 CFR §25.812. EASA (European Union Aviation Safety Agency): Recognizes photoluminescent and afterglow paints as approved alternatives to radioactive illumination for cockpit, cabin, and exterior aircraft markings. DGCA (Directorate General of Civil Aviation, India): Follows ICAO and FAA guidelines for emergency lighting and floor proximity escape path marking systems, encouraging the adoption of non-radioactive solutions in Indian-registered aircraft. AERB (Atomic Energy Regulatory Board, India): Regulates the handling, disposal, and licensing of radioactive substances. Our non-radioactive formulation falls outside AERB’s radioactive licensing requirements, simplifying compliance and ensuring safe integration in aviation systems. ICAO (International Civil Aviation Organization): Promotes the use of passive, power-free safety illumination in international civil aviation standards. By aligning with these international standards, Safelight Radium Paint ensures compatibility with current aerospace safety regulations and simplifies global export, certification, and installation processes. 🚀 Technical Advantages Self-Charging & Maintenance-Free: Absorbs natural or artificial light and glows for up to 12–18 hours without electricity or battery. Extreme Environment Resistant: Stable under wide temperature ranges, altitude fluctuations, humidity, and vibration. Lightweight & Thin Film: Adds negligible weight — a key requirement in aerospace applications. Non-Radioactive & Eco-Friendly: Complies with all EASA, FAA, DGCA, AERB, and ICAO safety standards, eliminating disposal or licensing complications. Customizable Formulation: Available in multiple glow intensities, colours, and coating systems for internal or external use. 🌐 Real-World Application Example During a power outage on a long-haul flight, cockpit illumination failed on a legacy aircraft. However, photoluminescent coatings on the instrument dials and critical switches continued to gl

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Brand Name | Safelight |

| Material | Radium-based paint |

| Color | Green In The Dark |

| Application | Emergency Evacuation Pathways |

| Style | Two pack |

| Abrasive Grain Sizes | 56 microns |

| Type | Night Glow Paint |

| Other Names | Radium Paint, Night Glow Paint , Autoglow Paint, Phosphorescent Paint, Luminous Paint, Glow In Dark |

| Product Code | ITV1 |

| Port | Mumbai |

| Payment Terms | L/C |

| Delivery Time | One week |

Safelight Radium Paint for Army & Defence Industry In modern defence and strategic sectors, Safelight Radium Paint is a mission-critical solution designed to enhance visibility, safety, and operational efficiency under extreme conditions. Developed using advanced photoluminescent technology, this high-performance coating absorbs ambient light and emits a bright, long-lasting glow in darkness — without any external power source. It provides a fail-safe visibility layer essential for battlefield operations, defence installations, weapons systems, and emergency evacuation routes. 🪖 Critical Role in Defence Operations Defence environments often involve low-visibility, high-risk conditions — from night missions and underground bunkers to power failures during combat situations. Safelight Radium Paint acts as a passive illumination system, ensuring uninterrupted visibility when conventional lighting is compromised. Its applications include: Military Equipment & Vehicles: Marking control panels, switchboards, weapon mounts, and dashboards in tanks, armoured vehicles, submarines, and aircraft. Ammunition Storage & Bunkers: Identifying safe paths, exit routes, and hazard areas in ammunition depots, shelters, and tunnels. Runways & Helipads: Marking landing zones and perimeter boundaries for night-time operations in forward bases. Soldier Equipment & Gear: Enhancing visibility on personal equipment, helmets, tactical kits, and communication devices during night operations. Missile Launch Pads & Control Rooms: Highlighting emergency shut-offs, valve positions, and control indicators for rapid response under blackout or combat scenarios. 🛰️ Defence & Strategic Organisation Compliance Safelight Radium Paint is engineered to align with the stringent operational and safety standards required by leading defence, aerospace, and research organisations. Its non-radioactive, eco-safe formulation meets the expectations and compliance frameworks of: DRDO (Defence Research and Development Organisation): For use in indigenous defence systems, missile launch sites, bunkers, laboratories, and critical infrastructure. ISRO (Indian Space Research Organisation): Suitable for spaceport facilities, launch complexes, and emergency evacuation marking in high-value installations. BSF (Border Security Force) & CRPF (Central Reserve Police Force): Ideal for border outposts, command centres, communication shelters, and surveillance infrastructure. IAF, IN, and IA (Indian Air Force, Navy, and Army): Deployed on aircraft ground support systems, warship interiors, ammunition chambers, and field command posts. CMIE & Strategic Command Centres: Supports mission-critical operations with reliable passive visibility in power-restricted or high-risk environments. AERB (Atomic Energy Regulatory Board): Confirms the paint is non-radioactive and free from radiological licensing requirements, ensuring easy deployment across sensitive facilities. DGCA (Directorate General of Civil Aviation) & EASA (European Union Aviation Safety Agency): Compliance-ready for defence aviation platforms and dual-use aerospace systems. ICAO & NATO Guidelines: Compatible with international safety standards for illumination, emergency evacuation, and equipment marking. ⚙️ Technical Advantages Non-Powered Operation: Glows for 12–18 hours after exposure to light — no wiring, batteries, or maintenance required. Extreme Durability: Resistant to vibration, abrasion, temperature extremes, humidity, and chemical exposure. Ultra-High Visibility: Provides clear guidance in total darkness, smoke, dust, and blackout conditions. Eco-Friendly & Safe: Free from radioactive materials, meeting DRDO, ISRO, AERB, DGCA, EASA, and NATO safety protocols. Custom Formulations: Available for metals, concrete, composite structures, and defence-grade coatings. 🔥 Real-World Strategic Applications During a simulated blackout drill at a missile command site, standard lighting wa

| Business Type | Manufacturer, Exporter |

| Brand Name | Safelight |

| Material | Radium-based paint |

| Color | Green In The Dark |

| Application | Suitable For Painting Tunnels And Dark Areas |

| Style | Two pack |

| Abrasive Grain Sizes | 56 microns |

| Type | Night Glow Paint,Nihgt Glow |

| Other Names | Radium Paint, Night Glow Paint , Autoglow Paint, Phosphorescent Paint, Luminous Paint, Glow In Dark |

| Manufacturer | Indra Technologies |

| Product Code | ITV1 |

| Port | Mumbai |

| Payment Terms | L/C |

| Delivery Time | One week |

ChatGPT said: Safelight Radium Paint for Commercial Complexes – Advanced Photoluminescent Safety Solution for Modern Buildings In today’s urban landscape, commercial complexes such as office towers, IT parks, business centers, and mixed-use buildings are operational hubs where thousands of people work, visit, and commute daily. Ensuring their safety during emergencies is not just a legal requirement — it’s a responsibility. Safelight Radium Paint, also known as Glow in Dark Paint, Night Glow Paint, Photoluminescent Paint, Luminous Paint, or Phosphorescent Paint, is an innovative passive safety coating designed to provide continuous, self-illuminating visibility and guide occupants to safety during critical situations — even in total darkness. By absorbing natural or artificial light during normal operations, Safelight Radium Paint emits a bright, visible glow for 10–12 hours when lighting fails. This ensures safe evacuation and visibility during emergencies such as fire, earthquake, explosion, chemical leak, power outage, or flood, reducing panic and preventing injuries. 🌟 Key Features and Safety Advantages Continuous Visibility in Blackouts: Even during complete power failures, Safelight Radium Paint glows brightly without electricity, clearly indicating exit routes, staircases, corridors, assembly points, and safety equipment locations. This ensures safe evacuation and prevents accidents in densely populated buildings. Life-Saving Safety Infrastructure: In emergencies where visibility is critical, such as during fires or explosions, Photoluminescent Paint acts as a reliable, maintenance-free guide that leads people to safety, significantly reducing evacuation time and confusion. Cost-Effective Alternative to Emergency Equipment: Installing and maintaining conventional emergency systems such as standby generators, emergency lights, or battery-powered lamps can be expensive and require regular upkeep. Safelight Radium Paint offers a one-time, maintenance-free solution that lasts over 5 years and requires no power, making it an economical substitute. Insurance Premium Savings: By enhancing passive safety infrastructure with Luminous Paint and Phosphorescent Paint, commercial buildings are often classified as lower risk by insurance providers, resulting in significant reductions in annual insurance premiums and long-term operational savings. Compliance and Safety Audit Support: Photoluminescent markings help commercial complexes meet fire safety codes, building regulations, and emergency preparedness standards, improving audit performance and enhancing building certifications. 🏢 Applications in Commercial Buildings Emergency exits, staircases, and corridors Firefighting and safety equipment areas (extinguishers, hydrants, alarms) Lifts, escalators, and elevator lobbies Parking areas, basements, and service corridors Meeting rooms, lobbies, and assembly points Emergency signage and directional pathways 📊 Case Study: Photoluminescent Safety Saves Lives During a Fire A multi-storey commercial tower in Mumbai housing over 2,000 employees installed Safelight Photoluminescent Paint on all emergency pathways, staircases, exit doors, and basement parking areas. A few months later, an electrical fire caused a complete power shutdown across the building, disabling conventional lighting and backup systems. Despite the blackout, the Glow in Dark Paint illuminated escape routes and safety points for more than 10 hours, enabling all occupants to evacuate safely and in an orderly manner within minutes. The incident resulted in zero casualties and minimal property damage. The building’s insurer later provided a 14% reduction in annual premium, citing improved passive safety measures and reduced risk exposure. ✅ Why Choose Safelight Radium Paint for Commercial Complexes? Self-charging and maintenance-free – no external power required. Long-lasting performance – glows effectively for 5+ years after a sin

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Brand Name | Safelight |

| Material | Radium-based paint |

| Color | Glow In The Dark |

| Application | Improves Visibility, Worker Safety, And Evacuation |

| Style | Two pack |

| Abrasive Grain Sizes | 56 microns |

| Type | Photoluminescent Paint |

| Other Names | Radium Paint, Night Glow Paint , Autoglow Paint, Phosphorescent Paint, Luminous Paint, Glow In |

| Product Code | ITV1 |

| Port | Mumbai |

| Payment Terms | L/C |

| Delivery Time | One week |

Safelight Radium Paint for Commercial Motor Vehicles Commercial motor vehicles — including trucks, buses, trailers, and vans — are critical to the logistics, transportation, and goods movement industry. Night-time driving, poor weather conditions, power failures, and long-haul operations create visibility challenges that can lead to accidents, collisions, and cargo damage. Safelight Radium Paint offers a photoluminescent, self-illuminating solution that enhances vehicle safety by glowing in the dark after absorbing natural or artificial light — without electricity or batteries. 🚛 Applications in Commercial Vehicles Safelight Radium Paint can be applied across multiple areas of commercial motor vehicles to improve visibility, operational safety, and regulatory compliance: Vehicle Body Markings: Glow on side panels, rear bumpers, wheel arches, and vehicle edges to increase night-time visibility to other drivers. Cargo & Trailer Sections: Highlight load boundaries, tail gates, and structural frames for safer handling and transportation. Emergency Exits & Doors: Illuminated marking on rear doors, sliding panels, and access points for easier operation in darkness or during emergencies. Driver Cabins & Instrument Panels: Marking critical dials, switches, and control indicators to assist drivers during low-light conditions. Fleet Identification & Lane Guidance: Glow markings for multi-vehicle fleets improve visibility in convoys, highways, and urban roads. Truck & Bus Steps: Highlight entry steps, ladders, and handrails for passenger and crew safety. Wheel Guards & Mud Flaps: Edge markings for enhanced vehicle outline recognition on highways. 🛣️ Importance in Road Safety Reduces night-time accidents due to improved vehicle visibility in dark or unlit areas. Assists drivers in safe manoeuvring, especially on highways, narrow lanes, and city traffic. Highlights emergency exits and cargo zones for faster and safer access during breakdowns or accidents. Enhances fleet safety, ensuring vehicles are visible from long distances even without streetlights. 🏢 Compliance with Transport & Safety Authorities Safelight Radium Paint is compliant with standards and recommended for projects under various transportation authorities: MoRTH (Ministry of Road Transport & Highways, India) – for national and state highways. RTO & Vehicle Safety Guidelines – for commercial fleet marking and passenger transport vehicles. IRDA & Fleet Management Companies – for fleet safety compliance and passenger protection. AERB, DGCA, EASA – ensuring non-radioactive, eco-friendly, and internationally compliant solutions. Logistics & Transport Corporations – for safer cargo transport, night operations, and maintenance zones. ⚙️ Key Technical Advantages Self-Illuminating & Power-Free: Glows for 12–18 hours after light exposure. High Visibility: Clearly visible from nearly 800–1000 m in complete darkness. Durable & Weather-Resistant: Withstands rain, vibration, UV exposure, dust, and road grime. Eco-Friendly & Non-Radioactive: Safe for vehicles, passengers, and the environment. Cost-Effective & Low-Maintenance: Reduces reliance on reflective tapes, external lights, and frequent repainting. 🚚 Real-World Application Scenario On a fleet of logistics trucks operating overnight on highways, Safelight Radium Paint on body edges, mud flaps, and rear doors remained bright for over 14 hours, enhancing visibility and preventing multiple near-miss collisions. Similarly, in urban bus fleets, glowing steps, handrails, and cabin markings improved passenger boarding and disembarking safety during unlit night-time operations. 🌐 Smart, Passive Safety Solution for Commercial Vehicles From trucks and trailers to passenger buses and fleet vehicles, Safelight Radium Paint provides a power-independent, maintenance-free visibility solution that improves safety, reduces accidents, and enhances operational efficiency. Fully compliant wit

| Business Type | Manufacturer, Exporter |

| Brand Name | Safelight |

| Material | Radium-based |

| Color | Green In The Dark |

| Application | Emergency Evacuation Pathways |

| Style | Two pack |

| Abrasive Grain Sizes | 56 microns |

| Type | Night Glow |

| Other Names | Radium Paint, Night Glow Paint , Autoglow Paint, Phosphorescent Paint, Luminous Paint, Glow In |

| Country of Origin | India |

| Packaging Size | 1 L |

| Product Code | ITV1 |

| Port | Mumbai |

| Payment Terms | L/C |

| Delivery Time | One week |

| Packaging Details | Two pack |

ChatGPT said: Safelight Radium Paint for Crude Oil Refineries – Advanced Photoluminescent Safety Coating for High-Risk Industrial Environments Crude oil refineries operate in some of the most hazardous and high-risk industrial conditions, where the presence of flammable materials, high-pressure systems, complex pipelines, and explosive atmospheres makes safety and emergency preparedness absolutely critical. In such environments, even a brief power failure or visibility loss during an emergency can lead to catastrophic consequences. Safelight Radium Paint, also known as Glow in Dark Paint, Night Glow Paint, Photoluminescent Paint, Luminous Paint, or Phosphorescent Paint, is a cutting-edge safety coating designed to provide continuous, maintenance-free visibility and guide personnel safely even in complete darkness. By absorbing natural or artificial light during regular operations, this advanced coating glows brightly for 10–12 hours without any electricity, helping workers navigate, evacuate, and locate safety equipment during critical situations. 🛢️ Key Safety Benefits in Refinery Environments Reliable Visibility During Emergencies: Refineries are highly vulnerable to fire, explosion, gas leaks, chemical spills, and power outages. Safelight Radium Paint ensures that escape routes, emergency exits, safety signage, and critical pathways remain clearly visible even when conventional lighting systems fail. Life-Saving Evacuation Tool: During high-risk incidents where seconds can mean the difference between life and death, Photoluminescent Paint acts as a silent safety guide, leading personnel safely toward exits, muster points, and emergency shelters. Cost-Effective Alternative to Conventional Safety Systems: Backup power systems, emergency lamps, and standby generators require heavy capital investment, regular maintenance, and continuous energy consumption. Safelight Radium Paint is a one-time, low-cost application that requires no maintenance, no power, and no operational expense for over 5 years — making it a highly economic substitute for traditional emergency lighting. Reduction in Insurance Premiums: Insurers often consider facilities equipped with Luminous Paint and Phosphorescent Paint as lower-risk operations. Installing such passive safety measures can lead to significant reductions in annual insurance premiums, translating into long-term financial savings. Regulatory Compliance and Safety Audit Readiness: Photoluminescent safety markings help refineries comply with OISD (Oil Industry Safety Directorate) norms, fire safety codes, and emergency evacuation guidelines, ensuring successful safety audits and certification processes. 🏭 Applications in Crude Oil Refineries Emergency exits, staircases, corridors, and evacuation pathways Control rooms, sub-stations, and pump houses Firefighting and safety equipment zones (extinguishers, alarms, hydrants, PPE stations) Hazardous chemical storage areas and gas manifold zones Pipelines, catwalks, platforms, and loading/unloading bays Assembly points, muster zones, and first-aid stations 📊 Case Study: Successful Evacuation During an Explosion Incident A major crude oil refinery in Gujarat installed Safelight Photoluminescent Paint on all evacuation routes, emergency doors, safety equipment locations, and high-risk operational zones as part of a safety modernization initiative. A few months later, a valve malfunction caused a fire and subsequent power failure in a processing unit during the night shift. Despite the sudden blackout and rising panic, the Glow in Dark Paint provided bright, visible guidance throughout the affected area. Workers were able to follow illuminated escape routes and reach assembly points within minutes, resulting in zero injuries and no loss of life. The refinery’s post-incident safety audit noted a 42% reduction in evacuation time compared to previous drills. The insurance company also rewarded the facility with a 16% re

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Color | Green |

| Shape | Square |

| Finishing | Polished |

| Material | PU |

| Brand Name | Safelight |

| Handle Material | Polueurathane |

| Condition | New |

| Stone Form | Block |

| Product Code | ITV1 |

| Port | Mumbai |

| Payment Terms | L/C |

| Delivery Time | One week |

Safelight Radium Paint for Curved Stones & Quarter Stones Road safety infrastructure is incomplete without clear, visible boundary markers such as curved stones, quarter stones, and roadside delineators. These small but critical components play a vital role in guiding drivers, defining road geometry, and preventing accidents — especially on curves, bends, medians, and sharp turns. However, conventional paints on these stones lose visibility at night or during poor weather, significantly increasing accident risks. Safelight Radium Paint is a revolutionary photoluminescent safety coating engineered to solve this problem by providing long-lasting, self-illuminating visibility without the need for electricity or external lighting. By absorbing daylight or artificial light and re-emitting a bright glow for 12–18 hours, it ensures road markers remain visible even in total darkness, heavy rain, fog, or power failure. 🛣️ Critical Safety Role of Curved Stones & Quarter Stones Curved and quarter stones are often overlooked, but they serve as visual guides that define road boundaries and alignment. When coated with Safelight Radium Paint, they become powerful, passive safety tools for night-time navigation. Applications include: Sharp Curves & Hairpin Bends: Glowing markers guide drivers in real time, reducing accidents on winding roads, hilly terrains, and ghat sections. Road Edges & Shoulders: Clearly visible boundaries prevent vehicles from veering off the road at night. Bridges & Flyovers: Enhanced visibility of quarter stones along bridge edges ensures safe vehicle movement even in low light or foggy conditions. Medians & Road Dividers: Bright luminescent coating on median stones improves lane discipline and helps drivers anticipate road geometry. Tunnels & Underpasses: Photoluminescent edge markers guide vehicles where natural light is unavailable. Approach Roads & Exit Ramps: Visible curved stones improve lane transitions and prevent collisions at highway exits and entry points. 🚦 Importance for Night-Time Road Safety Over 60% of accidents on curved roads and exit ramps occur at night due to poor visibility of roadside stones and markers. Safelight Radium Paint directly addresses this challenge by: Providing uninterrupted visibility even when headlights fail. Allowing drivers to judge curve angles and distances well in advance. Reducing accidents in fog, heavy rain, or blackout conditions. Acting as a cost-effective alternative to installing expensive roadside lighting systems. 🏗️ Compatible with All Road Safety Departments Safelight Radium Paint is manufactured to meet stringent national and international safety standards and is suitable for projects under: NHAI (National Highways Authority of India): For highways, expressways, and flyovers. PWD (Public Works Department): For municipal roads, dividers, and urban infrastructure. BRO (Border Roads Organisation): For hilly roads, mountain passes, and border roads. IRCON, RVNL, RDSO: For railway approach roads and trackside safety zones. Municipal Corporations & Smart City Projects: For city roads, traffic islands, and footpaths. AERB, DGCA, EASA: For safety compliance in critical transport and defence corridors. ⚙️ Key Technical Advantages Self-Illuminating & Power-Free: Glows for 12–18 hours after light exposure. High Visibility Distance: Visible from nearly 800–1000 m — even without vehicle headlights. Durable & Weather-Resistant: Withstands rain, heat, dust, vibration, and traffic impacts. Eco-Friendly & Non-Radioactive: Safe for highways, tunnels, and urban environments. Cost-Effective & Maintenance-Free: Reduces dependence on streetlights and frequent repainting. 🚗 Real-World Performance Example On a mountain highway in Himachal Pradesh, curved and quarter stones coated with Safelight Radium Paint provided continuous visibility for over 15 hours during night operations, helping vehicles navigate hairpin bends and steep

| Business Type | Manufacturer, Exporter |

| Condition | New |

| Color | Radium Green In Dark & White In Daylight |

| Brand Name | Safelight |

| Warranty | 5years |

| Country of Origin | India |

| Glow Time | 4 hours after Glow |

| Type | Night Glow |

| Manufacturer | Indra Technologies |

| Product Code | ITV1 |

| Port | Mumbai |

| Payment Terms | L/C |

| Delivery Time | One week |

ChatGPT said: Safelight Radium Paint for Electric Power Plants – Advanced Photoluminescent Safety Coating for Critical Energy Infrastructure Electric power plants are among the most critical facilities in modern infrastructure — powering cities, industries, hospitals, and essential services. However, they also operate in high-risk environments where the presence of high-voltage equipment, steam pressure, rotating machinery, fuel systems, and confined areas makes safety a top priority. During emergencies such as power outages, fires, explosions, floods, or earthquakes, visibility loss can lead to severe accidents, injuries, or catastrophic failures. Safelight Radium Paint, also known as Glow in Dark Paint, Night Glow Paint, Photoluminescent Paint, Luminous Paint, or Phosphorescent Paint, is a cutting-edge passive safety solution engineered specifically for power generation facilities. It absorbs natural or artificial light during normal operations and automatically emits a bright, long-lasting glow for 10–12 hours in darkness — ensuring safe navigation, quick evacuation, and reliable visibility when it matters most. ⚡ Key Safety Advantages for Power Generation Facilities Uninterrupted Emergency Visibility: Power plants are particularly vulnerable to sudden blackouts, fires, short circuits, or turbine failures. Safelight Radium Paint ensures that escape routes, emergency exits, staircases, switchgear rooms, and control room pathways remain visible even when all lighting systems fail. Life-Saving Guidance During Critical Incidents: In the event of fires, explosions, coolant leaks, boiler ruptures, or seismic events, Photoluminescent Paint acts as a reliable, maintenance-free guide, helping personnel evacuate safely and locate essential safety equipment without panic. Cost-Effective Alternative to Traditional Safety Systems: Standby generators, emergency lamps, and battery-operated lighting require significant capital investment, regular maintenance, and high operational costs. Safelight Radium Paint is a one-time, low-cost solution with zero energy consumption and no maintenance needs for over 5 years, making it an economic substitute for many conventional systems. Insurance Premium Reduction: Facilities equipped with Luminous Paint and Phosphorescent Paint are often categorized as lower-risk operations by insurers. This can lead to substantial reductions in annual insurance premiums, delivering long-term financial benefits. Supports Safety Audits and Compliance: Photoluminescent safety markings help power plants comply with fire safety codes, OSHA, NFPA, and ISO safety standards, strengthening safety audits and regulatory inspections. 🏭 Applications of Safelight Radium Paint in Power Plants Emergency exits, stairways, and evacuation routes Turbine halls, control rooms, and switchgear areas Transformer yards, cable tunnels, and basements Fuel handling and chemical storage zones Firefighting equipment areas (hydrants, extinguishers, alarms, PPE stations) Assembly points, muster areas, and safety signage 📊 Case Study: Successful Evacuation During a Blackout A 500 MW coal-fired power plant in Maharashtra implemented Safelight Photoluminescent Paint across all evacuation routes, control room corridors, safety equipment stations, and turbine floors. Three months later, a transformer explosion triggered a complete blackout and smoke infiltration across two operational floors. Despite total darkness and panic, Glow in Dark Paint illuminated all escape routes, staircases, and safety signage for more than 12 hours. Over 600 workers and engineers evacuated safely within minutes, with zero casualties or injuries. Following the incident, the power utility reported a 38% reduction in evacuation time, and the facility’s insurer offered a 15% reduction in annual premiums due to the enhanced passive safety measures. ✅ Why Choose Safelight Radium Paint for Power Plants? Self-charging and maintenance-free –

| Business Type | Manufacturer, Exporter |

| Brand Name | Safelight,Safelilght |

| Material | Radium-based,night Glow paint |

| Color | Green In The Dark |

| Application | Emergency Evacuation Pathways |

| Style | Two pack |

| Abrasive Grain Sizes | 56 microns |

| Type | Night Glow Paint |

| Other Names | Radium Paint, Night Glow Paint , Autoglow Paint, Phosphorescent Paint, Luminous Paint, Glow In Dark |

| Warranty | 3 years |

| Country of Origin | India |

| Size | 65 |

| Product Code | ITV1 |

| Port | Mumbai |

| Payment Terms | L/C |

| Delivery Time | One week |

| Packaging Details | Two pack PU |

ChatGPT said: Safelight Radium Paint for Electronics Manufacturing Plants – Photoluminescent Safety Coating for High-Tech Environments In electronics manufacturing facilities, where precision, sensitive equipment, and uninterrupted processes are essential, even a brief power outage or emergency can cause severe safety risks, production downtime, and financial losses. Safelight Radium Paint, also known as Glow in Dark Paint, Night Glow Paint, Photoluminescent Paint, Luminous Paint, or Phosphorescent Paint, is a revolutionary passive safety coating designed to ensure continuous visibility, safe evacuation, and enhanced emergency preparedness — without relying on electricity. By absorbing ambient light (natural or artificial) during normal operations, Safelight Radium Paint automatically emits a bright, long-lasting glow for 10–12 hours in darkness. This provides a clear, visible pathway for workers and technicians during emergencies such as fire, explosion, earthquake, chemical leaks, floods, or sudden power failures, helping avoid accidents and ensuring a safe, organized evacuation. 🌟 Key Safety Advantages and Benefits Uninterrupted Emergency Guidance: Even during total power loss, Safelight Radium Paint glows brightly, guiding personnel toward exit doors, staircases, emergency assembly points, and safety equipment — ensuring rapid, panic-free evacuation. Critical for Sensitive Environments: Electronics plants house static-sensitive components, hazardous chemicals, and high-value machinery. In such environments, conventional lighting systems may fail or cause additional hazards during emergencies. Photoluminescent Paint provides maintenance-free, reliable illumination without any electrical risk. Cost-Effective Safety Investment: Traditional systems like standby generators, emergency lamps, and battery-powered exit lights involve heavy installation costs, periodic maintenance, and ongoing power expenses. Safelight Radium Paint, on the other hand, is a one-time, low-cost solution that remains effective for over 5 years, requiring no electricity and zero maintenance. Insurance Premium Reduction: Many insurance companies classify facilities with enhanced passive safety measures — like Luminous Paint and Phosphorescent Paint — as lower risk. Electronics manufacturers using these systems often receive significant discounts on insurance premiums, leading to substantial long-term savings. Regulatory Compliance and Safety Audits: The use of photoluminescent safety markings improves compliance with fire safety codes, occupational safety guidelines, and EHS (Environment, Health & Safety) standards, strengthening audit performance and certification readiness. 🏭 Applications in Electronics Manufacturing Plants Emergency exits, staircases, and evacuation routes Firefighting and safety equipment zones (extinguishers, alarms, hydrants) Hazardous chemical storage areas and cleanrooms Control panels, power distribution areas, and assembly points Corridors, floor demarcations, and restricted zones Basement pathways and service tunnels 📊 Case Study: Safe Evacuation During a Power Failure A leading electronics assembly plant in Noida, employing over 1,200 people, installed Safelight Photoluminescent Paint across its emergency routes, staircases, cleanroom exits, and critical equipment areas. A few months later, a short-circuit caused a complete power outage during the evening shift, disabling lighting and halting operations. Despite the blackout, Glow in Dark Paint illuminated all exit pathways, enabling the entire workforce to evacuate safely within minutes with zero injuries or accidents. The company’s risk assessment report noted a 40% reduction in evacuation time, and the facility’s insurance provider later offered a 15% reduction in annual premiums, recognizing the improved safety infrastructure. ✅ Why Choose Safelight Radium Paint for Electronics Plants? Self-illuminating and maintenance-free – charge

| Business Type | Manufacturer, Exporter |

| Other Names | Radium Paint, Night Glow Paint , Autoglow Paint, Phosphorescent Paint, Luminous Paint, Glow In Dark |

| Type | Night Glow Paint |

| Application | Emergency Evacuation Pathways,Safety |

| Color | Green In The Dark,Green in dark |

| Material | Radium-based |

| Brand Name | Safelight |

| Style | Two pack |

| Abrasive Grain Sizes | 56 microns |

| Country of Origin | India |

| Manufacturer | Indra Technologies |