- GST NO. : 27AQUPS9969A1ZW

indratechnologies@gmail.com

| Business Type | Manufacturer, Exporter |

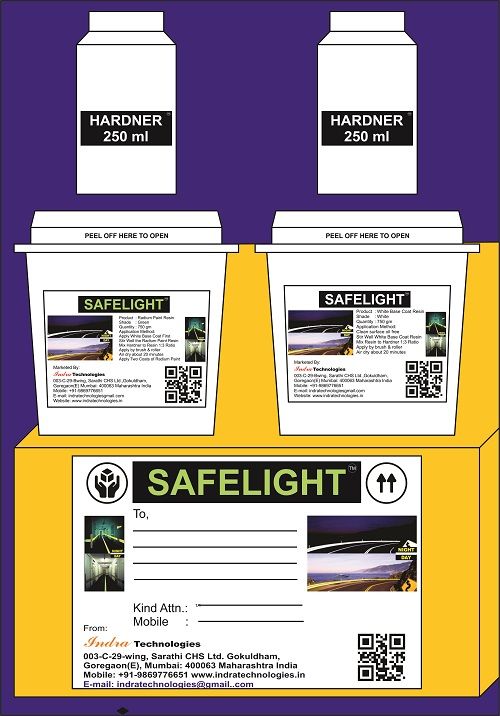

| Brand Name | Safelight,Safelilght |

| Material | Radium-based,night Glow paint |

| Color | Green In The Dark |

| Click to view more | |

Product Details

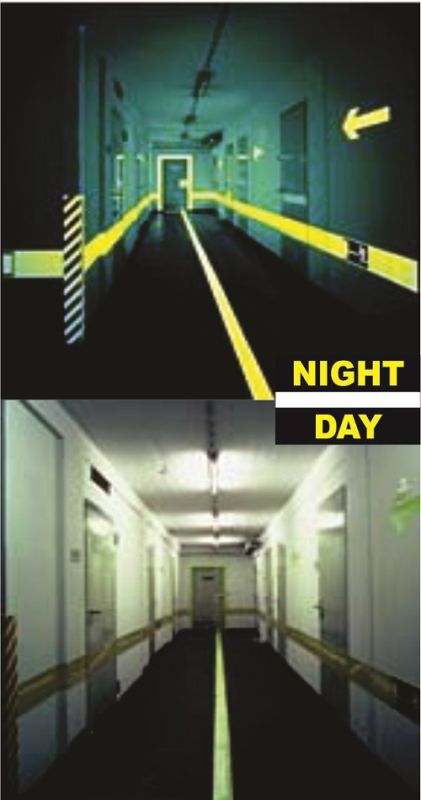

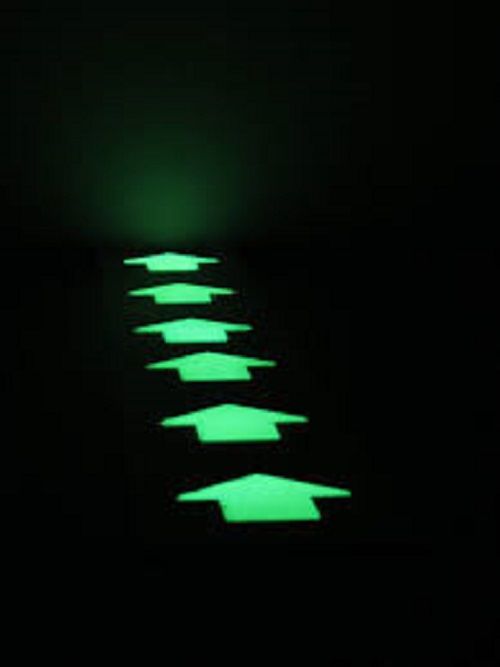

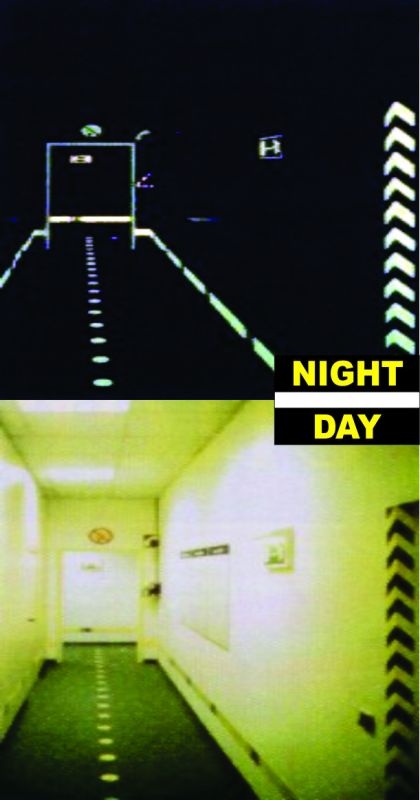

ChatGPT said: Safelight Radium Paint for Electronics Manufacturing Plants – Photoluminescent Safety Coating for High-Tech Environments In electronics manufacturing facilities, where precision, sensitive equipment, and uninterrupted processes are essential, even a brief power outage or emergency can cause severe safety risks, production downtime, and financial losses. Safelight Radium Paint, also known as Glow in Dark Paint, Night Glow Paint, Photoluminescent Paint, Luminous Paint, or Phosphorescent Paint, is a revolutionary passive safety coating designed to ensure continuous visibility, safe evacuation, and enhanced emergency preparedness — without relying on electricity. By absorbing ambient light (natural or artificial) during normal operations, Safelight Radium Paint automatically emits a bright, long-lasting glow for 10–12 hours in darkness. This provides a clear, visible pathway for workers and technicians during emergencies such as fire, explosion, earthquake, chemical leaks, floods, or sudden power failures, helping avoid accidents and ensuring a safe, organized evacuation. 🌟 Key Safety Advantages and Benefits Uninterrupted Emergency Guidance: Even during total power loss, Safelight Radium Paint glows brightly, guiding personnel toward exit doors, staircases, emergency assembly points, and safety equipment — ensuring rapid, panic-free evacuation. Critical for Sensitive Environments: Electronics plants house static-sensitive components, hazardous chemicals, and high-value machinery. In such environments, conventional lighting systems may fail or cause additional hazards during emergencies. Photoluminescent Paint provides maintenance-free, reliable illumination without any electrical risk. Cost-Effective Safety Investment: Traditional systems like standby generators, emergency lamps, and battery-powered exit lights involve heavy installation costs, periodic maintenance, and ongoing power expenses. Safelight Radium Paint, on the other hand, is a one-time, low-cost solution that remains effective for over 5 years, requiring no electricity and zero maintenance. Insurance Premium Reduction: Many insurance companies classify facilities with enhanced passive safety measures — like Luminous Paint and Phosphorescent Paint — as lower risk. Electronics manufacturers using these systems often receive significant discounts on insurance premiums, leading to substantial long-term savings. Regulatory Compliance and Safety Audits: The use of photoluminescent safety markings improves compliance with fire safety codes, occupational safety guidelines, and EHS (Environment, Health & Safety) standards, strengthening audit performance and certification readiness. 🏭 Applications in Electronics Manufacturing Plants Emergency exits, staircases, and evacuation routes Firefighting and safety equipment zones (extinguishers, alarms, hydrants) Hazardous chemical storage areas and cleanrooms Control panels, power distribution areas, and assembly points Corridors, floor demarcations, and restricted zones Basement pathways and service tunnels 📊 Case Study: Safe Evacuation During a Power Failure A leading electronics assembly plant in Noida, employing over 1,200 people, installed Safelight Photoluminescent Paint across its emergency routes, staircases, cleanroom exits, and critical equipment areas. A few months later, a short-circuit caused a complete power outage during the evening shift, disabling lighting and halting operations. Despite the blackout, Glow in Dark Paint illuminated all exit pathways, enabling the entire workforce to evacuate safely within minutes with zero injuries or accidents. The company’s risk assessment report noted a 40% reduction in evacuation time, and the facility’s insurance provider later offered a 15% reduction in annual premiums, recognizing the improved safety infrastructure. ✅ Why Choose Safelight Radium Paint for Electronics Plants? Self-illuminating and maintenance-free – charge