- GST NO. : 27AQUPS9969A1ZW

indratechnologies@gmail.com

| Business Type | Manufacturer, Exporter |

| Brand Name | Safelight |

| Material | Radium-based paint |

| Color | Green In The Dark |

| Click to view more | |

Product Details

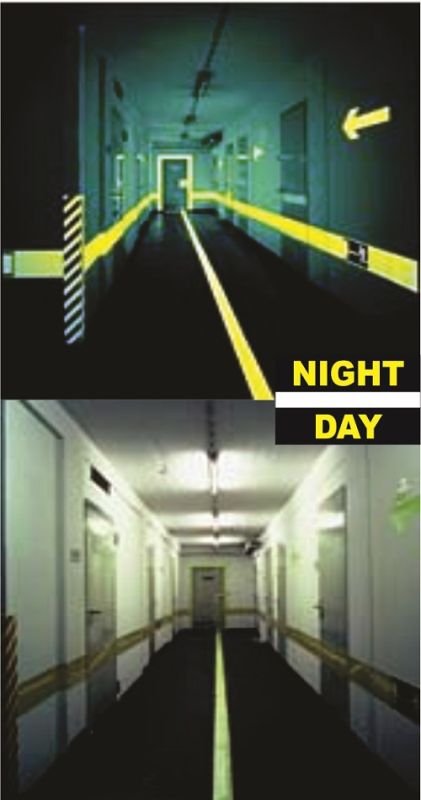

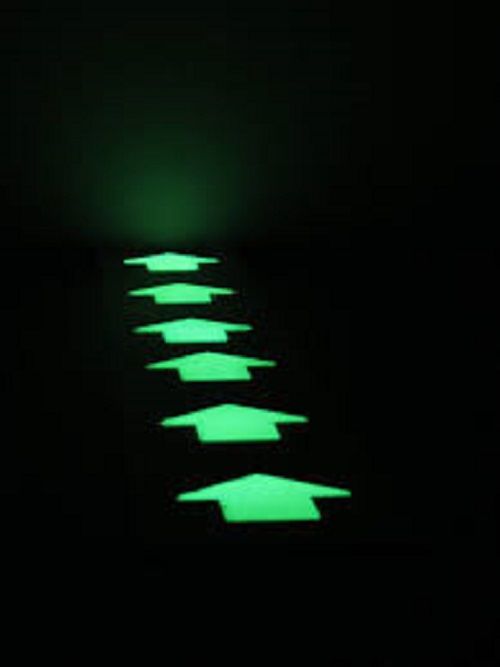

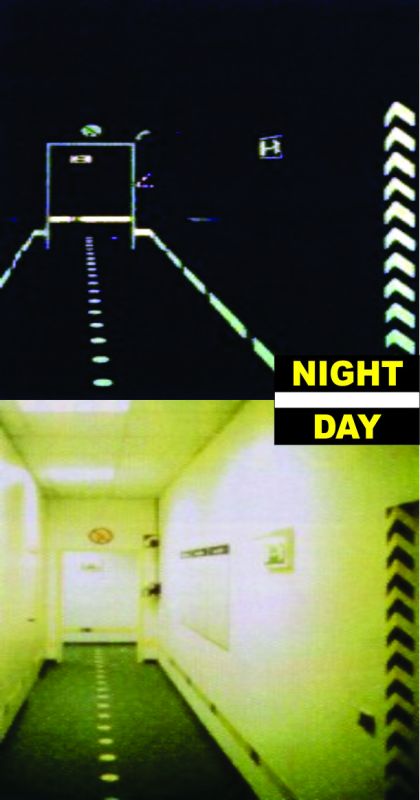

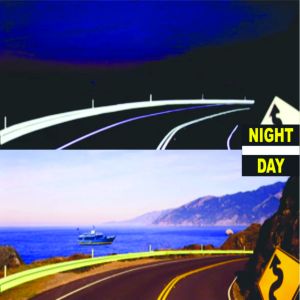

ChatGPT said: Safelight Radium Paint for Nuclear Power Plants – Critical Photoluminescent Safety Solution for High-Risk Energy Facilities Nuclear power plants are the backbone of modern energy infrastructure, supplying clean and continuous power to millions of homes and industries. However, they also represent some of the most sensitive, high-risk environments on Earth, where even a brief loss of visibility during an emergency can lead to catastrophic consequences. Due to their reliance on abundant cooling water, most nuclear facilities are located near coastal regions, which makes them particularly vulnerable to natural disasters such as tsunamis, sea water flooding, storm surges, or earthquakes. Safelight Radium Paint, also known as Glow in Dark Paint, Night Glow Paint, Photoluminescent Paint, Luminous Paint, or Phosphorescent Paint, is a cutting-edge safety innovation designed to protect life and infrastructure during such critical events. It absorbs light during normal operations and emits a bright, long-lasting glow for 10–12 hours in total darkness — ensuring safe navigation, evacuation, and emergency operations even during the worst conditions, such as blackouts, structural damage, or flooding. ☢️ Essential Safety Benefits for Nuclear Facilities Uninterrupted Visibility During Blackouts: In nuclear plants, power loss can halt critical cooling systems and monitoring equipment. Safelight Radium Paint ensures emergency exits, staircases, control room pathways, and radiation safety zones remain clearly visible even when every electrical system fails. Flood and Tsunami Resilience: Because many nuclear plants are located near the sea, they are at risk of flooding and water ingress during natural disasters. Even in submerged or partially flooded conditions, Photoluminescent Paint continues to glow underwater and in wet environments, guiding personnel safely toward exits, higher ground, or emergency stations. Crucial Support During Natural Disasters: During earthquakes, tsunamis, explosions, or coolant leaks, Luminous Paint provides continuous, non-electric illumination, reducing panic and enabling faster, safer decision-making in high-stress environments. Economic Alternative to Emergency Infrastructure: Traditional safety systems like emergency lamps, backup generators, and battery-powered lighting require significant investment and regular maintenance. Safelight Radium Paint is a low-cost, passive safety solution that requires no electricity, no batteries, and virtually no upkeep — operating effectively for over 5 years after a single application. Insurance and Compliance Benefits: Facilities equipped with Phosphorescent Paint are often rated as lower-risk by insurers, helping plant operators save significantly on annual insurance premiums while also improving safety audit scores and compliance with IAEA, NRC, and ISO safety standards. 🏭 Strategic Applications in Nuclear Power Plants Evacuation pathways, staircases, and emergency exits Control rooms, turbine halls, and containment building interiors Radiation safety corridors and reactor floor boundaries Fuel handling, spent fuel storage, and cooling system areas Firefighting equipment points, safety signage, and muster zones 📊 Case Study: Fukushima Daiichi – A Lesson in Emergency Visibility The 2011 Fukushima Daiichi nuclear disaster in Japan highlighted the catastrophic risks of losing visibility during extreme events. Following a massive earthquake and tsunami, the plant suffered complete power loss, disabling lighting and emergency systems. Flooding further complicated evacuation and response efforts, as critical routes and safety signage disappeared into darkness. Had Safelight Photoluminescent Paint been installed, pathways, exit points, and safety stations would have remained clearly illuminated for more than 10 hours without electricity, significantly improving the evacuation process and potentially reducing the scale of the disaste